- 【Alltruth Limited】Welcome to Alltruth Power(www.alltruthpower.com), We provide you professional power solutions.

- Make a call:138 5726 9602

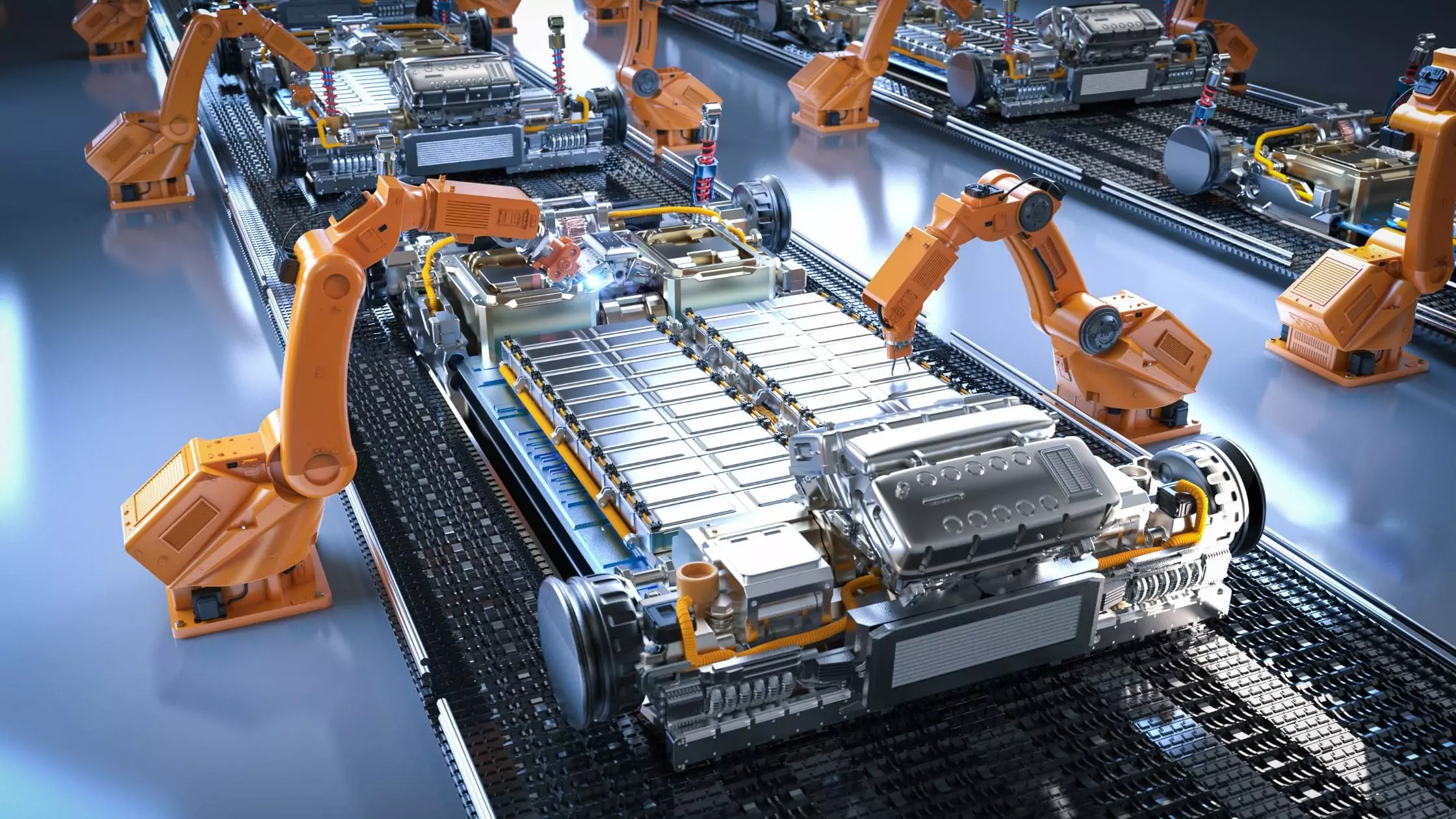

AGV charging usually happens in industrial charging environments due to the demanding nature of their operations. Automated guided vehicles are the “new rave” now, due to their efficiency and reduced cost. For a faster mode of transportation, most industries make use of AGVs as against other manual transportation methods.

However, one critical aspect of AGV operation is their reliance on batteries, which can impact productivity if not managed properly.

This article will provide comprehensive insights into AGV battery charging, emphasizing the importance of selecting the correct industrial battery charger to ensure optimal performance and uninterrupted operations.

What is an Automated Guided Vehicle (AGV)?

An Automated Guided Vehicle (AGV) is a sefl-propelled robotic vehicle used in modern logistics and manufacturing, engineered to navigate autonomously within industrial environments. These vehicles streamline processes by transporting goods and materials without human intervention, utilizing advanced technologies such as laser scanners, cameras, and inertial guidance systems.

How are AGVs Charged?

The different charging processes of AGVs are; manual charging stations, automatic charging systems, opportunity charging, battery swapping systems, and wireless charging

Charging Automated Guided Vehicles (AGVs) is integral to maintaining their continuous operation across various industrial environments. The process involves several sophisticated systems and technologies designed to ensure efficiency and safety.

What Type of Battery Does an AGV Use?

Every AGV (Automated Guided Vehicle) relies on an industrial battery to meet the high demands of continuous operation in industrial settings. Every industrial AGV battery is designed to provide reliable, long-lasting power, ensuring maximum productivity and efficiency.

Here’s an exploration of the different types of batteries used in AGVs, two of them being lead-acide batteries and lithium-ion batteries, highlighting their chemistry, capacity and preffered applications.

Lead-Acid Batteries

Lead-Acid batteries are one of the oldest types of rechargeable batteries and remain widely used in various industrial applications due to their reliability and cost-effectiveness:

- Cost Efficiency: Lead-acid batteries are less expensive on a per-watt basis compared to newer technologies, making them a viable option for budget-conscious operations.

- High Surge Currents: These batteries are capable of delivering high surge currents, making them suitable for applications requiring high power over short durations.

- Availability: Due to their long history and widespread use, lead-acid batteries are readily available and supported by a mature recycling infrastructure.

Technical Specifications:

- Voltage: Typically, each cell provides about 2 volts, with multiple cells connected in series to achieve the desired voltage for an AGV.

- Capacity: The capacity of lead-acid batteries for AGVs can vary widely, typically ranging from 100 Ah to 500 Ah depending on the specific application needs.

Applications:

- Lead-acid batteries are commonly used in AGVs for tasks that do not require extended operation away from charging facilities, such as in warehouses and distribution centers where charging stations can be easily accessed.

Lithium-Ion Batteries

Lithium-Ion (Li-ion) batteries are highly favored in modern AGV systems due to their excellent energy density and efficiency. Key characteristics include:

- High Energy Density: Li-ion batteries can store more energy per unit of weight compared to other types, making AGVs lighter and more efficient.

- Long Lifespan: These batteries typically endure more charge cycles before their capacity falls below operational levels.

- Fast Charging: Li-ion technology supports faster charging, which is crucial for minimizing downtime in continuous operation settings.

- Low Maintenance: Unlike batteries that require regular fluid checks and top-ups, Li-ion batteries are virtually maintenance-free.

Technical Specifications:

- Voltage: Ranges from 3.6 to 3.7 volts per cell.

- Capacity: Commonly used capacities in AGVs range from 100 Ah to 300 Ah, depending on the size and application of the vehicle.

Applications:

- Li-ion batteries are ideal for applications requiring high energy output and efficiency, such as in high-demand logistics and manufacturing environments.

Nickel-Metal Hydride Batteries

Nickel-Metal Hydride (NiMH) batteries are another popular choice for AGVs, known for their balance between cost and performance. Characteristics include:

- Good Energy Density: While not as high as Li-ion, NiMH batteries offer sufficient energy density for many standard AGV applications.

- Environmental Friendliness: NiMH batteries are less harmful to the environment compared to Nickel-Cadmium (NiCd) batteries, as they do not contain toxic cadmium.

- Moderate Cost: They provide a middle ground in terms of cost-effectiveness, between Li-ion and older battery technologies like lead-acid.

Technical Specifications:

- Voltage: Typically around 1.2 volts per cell.

- Capacity: Usually ranges from 85 Ah to 250 Ah, making them suitable for medium-duty applications.

Applications:

- NiMH batteries are well-suited for use in environments where temperature extremes are not a significant concern and where budget considerations are paramount.

Nickel-Cadmium Batteries

Nickel-Cadmium (NiCd) batteries have been a staple in the battery industry due to their robustness and reliability. Here are the essential characteristics and benefits of NiCd batteries for AGVs:

- Durability: NiCd batteries are known for their ability to withstand harsh conditions, including extreme temperatures and rough handling, making them suitable for industrial environments.

- Longevity: These batteries can endure a high number of charge-discharge cycles, which is beneficial for AGVs that require frequent power replenishments throughout their operational life.

- Performance: NiCd batteries offer stable voltage levels throughout the discharge cycle, ensuring consistent performance of AGVs during use.

Technical Specifications:

- Voltage: Typically about 1.2 volts per cell.

- Capacity: Ranges from 500 Ah to 1000 Ah, accommodating the energy needs of various AGV models.

Applications:

- Particularly effective in applications where the battery is subjected to complete discharge and immediate recharge cycles, which are common in round-the-clock industrial operations.

Ultra-Capacitors

Ultra-capacitors represent a cutting-edge technology in the field of energy storage, providing fast charging solutions for AGVs. Here’s what makes ultra-capacitors valuable:

- Rapid Charging: Ultra-capacitors can charge and discharge in seconds, which is ideal for AGVs that operate on tight schedules and need quick energy boosts.

- Efficiency: They are highly efficient at storing and releasing energy, which reduces energy loss during the charge cycle and enhances the overall efficiency of the AGV.

- Lifecycle: Ultra-capacitors have an exceptionally long lifecycle, capable of millions of charge-discharge cycles without significant degradation.

Technical Specifications:

- Energy Density: While lower than traditional batteries, the energy density of ultra-capacitors is sufficient for short-term energy supply during peak operational demands.

- Power Density: High power density allows for the quick release of energy, making them excellent for instantaneous power applications.

Applications:

- Ultra-capacitors are ideal for use in systems where AGVs require immediate power for acceleration or heavy lifting tasks within a logistic center or manufacturing plant.

Fuel Cells

Fuel cells represent a sophisticated energy solution for AGVs, offering several benefits over traditional battery systems:

- High Energy Efficiency: Fuel cells convert chemical energy from hydrogen fuel directly into electricity, offering higher efficiency rates compared to conventional batteries.

- Longer Operational Range: AGVs equipped with fuel cells can operate for longer durations without the need for frequent recharging, which is ideal for continuous operation settings.

- Quick Refueling: Unlike batteries that require hours to recharge, fuel cells can be refueled within minutes, significantly reducing downtime.

- Environmental Sustainability: Fuel cells produce only water and heat as byproducts, making them an environmentally friendly option compared to batteries that may contain harmful chemicals.

Technical Specifications:

- Energy Density: Fuel cells provide a much higher energy density compared to traditional batteries, allowing AGVs to carry less weight in power units and operate more efficiently.

- Lifespan: The lifespan of fuel cell systems often exceeds that of standard battery solutions, underpinning their suitability for long-term industrial applications.

Applications:

- Fuel cells are particularly advantageous in logistics and manufacturing sectors where AGVs require extended operational periods and minimal interruptions for charging.

What Are Automated Guided Vehicle (AGV) Battery Charging Systems?

AGV battery charging systems are designed to ensure that these robotic vehicles have sufficient power to perform tasks without significant interruptions. Most AGV chargers are designed for industrial battery charging environments due to their robust construction and advanced features. These chargers are built to withstand demanding industrial environments, offering durability against impact, vibration, and extreme temperatures.

AGV charging systems vary in complexity and type, each tailored to meet specific operational demands. Here’s a closer look at their roles and functions:

- Continuous Operation Support: AGV battery charging systems are crucial in facilitating near-continuous operations in industries like manufacturing and warehousing. By providing quick and efficient charging, these systems minimize downtime, enhancing productivity.

- Energy Management: Modern AGV charging systems incorporate advanced energy management technologies that help optimize power consumption. This not only reduces energy costs but also extends the lifespan of the AGV’s battery.

- Automated Charging Processes: Many AGV systems are equipped with automated charging stations that allow the vehicles to charge without manual intervention. When AGVs detect low battery levels, they navigate to the nearest charging station, dock themselves, and charge until they are ready to resume operations.

- Safety and Maintenance: Charging systems are also designed to maintain safety standards within operational environments. They include features that prevent overcharging, manage battery temperature, and mitigate risks of electrical faults, which could otherwise lead to operational hazards.

- Integration with AGV Management Systems: AGV charging systems are often integrated with central management systems that monitor and control a fleet of AGVs. This integration allows for real-time data transmission regarding the status of each AGV’s battery life, operational efficiency, and charging schedules.

What are the Different Types of AGV Charging Systems?

Automated Guided Vehicles (AGVs) require efficient and reliable charging systems to maintain continuous operation in various industrial settings. Understanding the different types of AGV charging systems is crucial for optimizing workflow and ensuring the longevity of the AGVs.

Overview of Different Methods Used to Charge AGVs

AGV charging systems can be broadly categorized into several types, each suited for specific operational needs and environments. Here’s a detailed overview:

- Manual Charging Systems

- Automatic Charging Systems

- Opportunity Charging Systems

Manual Charging Systems

Manual charging systems require the intervention of personnel to connect the AGVs to a charging station. This process involves physically plugging the AGV into a power source, usually when the vehicle is not in use during off-shift hours or scheduled downtimes.

Manual systems are compatible with various battery types but are most commonly used with lead-acid batteries due to their cost-effectiveness and availability.

Applicability:

This type of charging is suitable for smaller facilities or those with fewer AGVs, where manual intervention does not significantly impact operational efficiency.

Advantages

- Cost-Effective: Less infrastructure is required compared to automated systems.

- Simplicity: Easier to implement and maintain.

Drawbacks

- Labor-Intensive: Requires manual effort for plugging and unplugging each AGV.

- Higher Downtime: AGVs must be taken out of operation for charging.

Manual Battery Swapping

Manual battery swapping involves replacing a depleted battery with a fully charged one by hand. This process requires an operator to physically remove the spent battery from the AGV and replace it with a charged one, usually performed at designated battery stations.

Manual swapping is often used with lead-acid batteries due to their availability and lower initial cost. However, it can be adapted to other types of batteries depending on the specific requirements of the AGV.

Applicability

This method is suitable for smaller operations or those where automation of the battery swapping process does not justify the additional cost. It is particularly applicable in environments where the installation of sophisticated charging infrastructure is not feasible.

Advantages

- Cost-effective setup with minimal infrastructure requirements.

- Flexibility in handling various battery types.

Drawbacks

- Labor-intensive, requiring manual effort which can lead to increased operational costs.

- Potential for increased downtime during the battery swapping process.

Automatic Battery Swapping

Automatic battery swapping systems enhance the efficiency of AGV operations by automating the battery replacement process. These systems use robotic mechanisms to remove depleted batteries and install charged ones without human intervention.

These systems are typically designed to work with specific battery types that support quick-connect mechanisms, such as lithium-ion batteries, which offer the robustness and reliability needed for automated handling.

Applicability:

Ideal for high-volume, continuous operation settings where downtime significantly impacts productivity, such as in large manufacturing facilities and warehouses.

Advantages

- Significantly reduces downtime by swiftly swapping batteries.

- Decreases labor costs associated with manual battery changes.

Drawbacks

- Higher upfront cost due to the complex machinery involved.

- May require specific battery types that are more expensive.

Automatic Charging Systems

Automatic charging systems for AGVs are designed to minimize human intervention, enhancing efficiency and reducing downtime. These systems use sensors and docking technology to allow AGVs to connect to charging stations automatically when their battery levels are low.

Typically, automatic systems are paired with lithium-ion batteries due to their ability to support faster charging times and higher energy densities, which are conducive to quick, efficient charging cycles.

Applicability

Automatic charging is most applicable in high-throughput environments where downtime directly equates to lost productivity. Examples include large-scale manufacturing facilities and warehouses operating around the clock.

Advantages

- Reduced labor costs as no manual intervention is needed.

- Lower downtime since AGVs can charge themselves during operational breaks.

Drawbacks

- Higher initial setup and maintenance costs.

- Requires more sophisticated infrastructure.

Opportunity Charging Systems

Opportunity charging systems are designed to charge AGVs during short, opportune moments throughout their operational day. This might include times when the vehicle is waiting to load or unload goods. These systems can be equipped with contact poles or utilize advanced wireless charging technologies to enable a seamless, efficient transfer of power.

Opportunity charging systems are often implemented with advanced battery technologies like lithium-ion or gel lead-acid batteries, which can handle partial charges without affecting the battery’s longevity.

Applicability

This charging method is ideal for operations where AGVs have predictable downtime or idle periods, such as staging areas in warehouses or loading docks.

Advantages

- Enhances operational efficiency by reducing planned downtime for charging.

- Can extend the life of the battery by avoiding deep discharges.

Drawbacks

- May require significant changes to operational workflows to maximize charging opportunities.

- Infrastructure and technology costs can be high, especially for wireless systems.

Inductive (Wireless) Charging

Inductive charging for AGVs employs electromagnetic fields to transfer energy between two objects through electromagnetic induction. This method involves an induction coil creating an alternating electromagnetic field from within a charging base station, and a second induction coil in the AGV receives power from that field and converts it back into electrical energy to charge the battery.

Wireless charging systems are typically used with lithium-ion batteries due to their efficiency and high energy density, which are capable of quick recharging and long service life.

Applicability

Inductive charging is most suited for environments where high levels of cleanliness and safety are paramount, such as in pharmaceutical or food production facilities, where contactless charging eliminates the risk of electrical faults and reduces maintenance for charging equipment.

Advantages

- Reduced Wear and Tear: No physical connection is required, reducing mechanical wear.

- Increased Safety: Eliminates risks associated with electrical contacts, such as short circuits and sparks.

Drawbacks

- Higher Cost: Generally more expensive to install compared to conventional charging systems.

- Efficiency Concerns: Typically less efficient than direct-contact charging methods, with some energy lost during transmission.

Battery Management Systems (BMS)

A Battery Management System is an electronic system that manages a rechargeable battery (cell or battery pack), such as by protecting the battery from operating outside its safe operating area, monitoring its state, calculating secondary data, reporting that data, controlling its environment, and balancing it.

BMS are used with various types of batteries including lithium-ion, lead-acid, and nickel-metal hydride, optimizing their efficiency and lifespan.

Applicability

Battery Management Systems are crucial in high-demand applications where battery health directly influences the operational efficacy and safety, such as in automated warehouses and manufacturing facilities using AGVs extensively.

Advantages

- Enhanced Battery Safety: Protects against overcharging and deep discharging, which can extend battery life.

- Improved Performance: Ensures batteries operate within their optimal range for energy efficiency.

Drawbacks

- Complexity and Cost: Adds additional complexity and cost to the battery system.

- Maintenance Required: Needs regular updates and maintenance to handle new battery technology and operational data.

Solar Charging

Solar charging systems for AGVs utilize photovoltaic panels to convert sunlight directly into electrical energy, which is then used to charge the vehicle’s battery. This system typically includes solar panels mounted on the AGV or within the operational environment, a converter to transform the solar energy into a usable form, and a battery storage unit.

Solar charging systems are compatible with various types of batteries, but they are most commonly used with lithium-ion batteries due to their high energy density and efficiency.

Applicability

Solar charging is particularly suitable for AGVs operating in areas with ample sunlight exposure. It is ideal for outdoor operations or facilities with significant rooftop or open space that can accommodate solar panels.

Advantages:

- Sustainability: Reduces carbon footprint by using renewable energy.

- Cost-Effective: Decreases energy costs over time after initial setup.

- Low Maintenance: Solar panels require minimal maintenance once installed.

Drawbacks

- Initial Investment: High upfront costs for installation and integration.

- Dependent on Weather: Efficiency drops on cloudy or rainy days, requiring a backup energy source.

Capacitive Charging

Capacitive charging involves the transfer of electrical energy through capacitors, which store electrical energy in an electric field. This method uses plates or pads that create a capacitive connection between the charger and the AGV, enabling the transfer of energy without direct contact.

Capacitive systems can charge various types of batteries but are typically paired with nickel-metal hydride or lithium-ion batteries due to their ability to quickly absorb and store charge.

Applicability

This technology is best used in environments where high levels of precision and safety are necessary, such as in clean rooms or areas where explosive materials are handled, as it does not require electrical contacts that could spark.

Advantages

- Safety: No direct electrical contact reduces the risk of sparks.

- Efficiency: Fast charging capabilities and minimal energy loss during transfer.

Drawbacks

- Cost: Generally more expensive than traditional charging methods due to advanced technology.

- Infrastructure: Requires significant changes to existing infrastructure to accommodate capacitive charging stations.

How Do AGV Charging Systems Work?

The efficiency of AGVs largely depends on their charging systems, which need to ensure that these vehicles are powered adequately to perform their tasks without significant downtime. Here, we delve into the detailed process of how AGV charging systems function, adhering to the specified technical terms and structure.

- Connection Initiation:

- Automated Connection: Most AGV systems initiate a charging session using automated mechanisms that guide the vehicle to align with the charging station. This is crucial for maintaining continuous operations, especially in high-demand environments.

- Manual Assistance: In some setups, manual intervention might be necessary to ensure proper connection, especially in older models or less automated environments.

- Charging Mode Activation:

- Once the AGV is properly aligned and connected, the charging system activates. This involves several checks and balances to ensure safety and efficiency, including verifying the battery status and ensuring the electrical connections are secure.

- Energy Transfer:

- Direct Charging: This method involves direct current (DC) being supplied to the AGV’s battery, rapidly charging it up to the required level. The current’s intensity can vary depending on the battery type and the charging technology used.

- Inductive Charging: For setups equipped with wireless charging, an inductive transfer of power occurs. Here, electromagnetic fields transfer energy between two objects without physical contact, increasing safety and reducing wear and tear.

- Monitoring and Management:

- Throughout the charging process, the system monitors several parameters such as voltage, current flow, and temperature to prevent any potential issues like overheating or overcharging.

- Battery Management Systems (BMS) are often integrated to optimize the charging process and extend the battery’s life by regulating the charge cycle and ensuring the battery operates within safe limits.

- Disconnection:

- Automatic Disconnection: Once the battery reaches its optimal charge level, the system automatically disengages the connection to prevent overcharging, signaling the AGV that it is ready for operation.

- Manual Removal: In less automated systems, a manual disconnection might be required, where the operator physically disconnects the AGV from the charging station.

- Post-Charge Checks:

- After disconnection, post-charge checks are conducted to ensure the AGV is ready to resume its tasks. This includes a brief diagnostic to check for any errors or issues in the AGV’s systems that might have arisen during charging.

- Return to Operation:

- The AGV is then cleared to return to its operational duties, now fully charged. The efficiency and speed of this process are crucial in maintaining high productivity and minimizing downtime in industrial settings.

How to Choose the Right AGV Battery Charging System?

Here, we’ll explore several critical factors to consider when choosing AGV charger ensuring your charging system aligns perfectly with your operational requirements and AGV specifications. Selecting the appropriate Automated Guided Vehicle (AGV) battery charging system is crucial for optimizing the efficiency and effectiveness of your AGVs in any operational setting. This selection impacts not only the operational capacity but also long-term financial considerations and system adaptability.

Operational Requirements

Understanding the operational demands of your AGV fleet is essential in determining the right charging system. Different systems offer various advantages depending on the specific requirements of your operation.

Different Battery Chargers Type of Options Available

- Standard Plug-in Chargers: Commonly used due to their simplicity and cost-effectiveness. Ideal for operations where AGVs can afford downtime.

- Automatic Charging Stations: Best for high-demand environments where AGVs operate round the clock. These chargers minimize downtime by allowing AGVs to charge automatically without manual intervention.

- Opportunity Charging: Enables AGVs to charge during short breaks in operation, suitable for continuous use environments. This method can significantly enhance operational efficiency by reducing idle time.

Infrastructure Compatibility

The existing infrastructure of your facility will also play a significant role in deciding the right AGV charging system:

- Space Availability: Some charging systems require more space than others. Assess whether your facility can accommodate large charging stations or if more compact solutions are needed.

- Power Supply Requirements: Verify that your facility’s power supply can support the chosen charging system without requiring costly upgrades.

Cost Considerations

Understanding the cost implications associated with different types of AGV charging systems is essential. Here are some key considerations:

- Initial Investment: The upfront cost of charging stations varies widely depending on the technology. For instance, advanced wireless charging systems tend to be more expensive than conventional plug-in chargers.

- Operational Costs: Consider the energy efficiency of the charging system. Systems that feature higher energy efficiency can reduce long-term operational costs significantly.

- Maintenance and Upkeep: Evaluate the expected maintenance costs. Systems with fewer mechanical parts, like wireless chargers, may offer lower long-term maintenance costs.

Charging Speed and Efficiency

Charging speed and efficiency are crucial for maintaining high operational throughput and minimizing downtime. Each charging system offers different capabilities and efficiencies:

- Fast Charging Systems: These are ideal for operations where AGVs are in constant use and downtime must be minimized. Fast chargers can be more expensive but provide quick power replenishment.

- Standard Charging: Often less costly and suitable for operations where AGVs can afford longer downtime periods.

- Opportunity Charging: Allows AGVs to charge during brief downtimes throughout their operational cycle, enhancing efficiency without the need for long charging breaks.

Safety and Compliance

When selecting an AGV charging system, safety and regulatory compliance are paramount. Here’s what to consider:

- Regulatory Standards: Ensure the charging system meets local and international safety standards such as UL, CE, and others pertinent to your region.

- Built-in Safety Features: Look for systems with safety mechanisms like overcharge protection, temperature control, and emergency shutoff features.

- Risk Assessment: Evaluate potential safety risks associated with each type of charging system in your specific working environment.

Safety Protocols:

- Routine Checks: Regular maintenance and inspections should be scheduled to ensure all safety protocols are followed.

- Employee Training: Proper training must be provided to all personnel on safe handling and operating procedures for charging AGV batteries.

Flexibility and Scalability

To accommodate future growth and changes in operational demand, the chosen AGV charging system must be flexible and scalable.

- Modular Design: Charging systems with a modular setup can be easily expanded or reconfigured as your fleet grows or as operational needs change.

- Multi-battery Compatibility: Systems that can charge various types of batteries can save costs and offer greater operational flexibility.

- Software Integration: Look for systems that offer seamless integration with existing warehouse or factory management software to optimize charging schedules and energy use.

Maintenance and Support

Maintenance and support are crucial for minimizing downtime and extending the life of AGV battery charging systems. Here’s what you need to consider:

- Availability of Support: Ensure that the manufacturer or provider offers comprehensive after-sales support, including customer service and technical assistance.

- Maintenance Requirements: Some charging systems may require more frequent maintenance than others. Opt for systems that are easier to maintain and come with clear maintenance guidelines.

- Warranty and Service Agreements: Check the warranty period and the specifics of the service agreements. Longer warranties and inclusive service agreements can significantly reduce long-term costs.

Technological Advancements

Staying updated with technological advancements can significantly impact the efficiency and capabilities of AGV charging systems. Consider the following:

- Adaptability to Future Technologies: With the rapid evolution of battery technology, choose a system that is adaptable to future advancements.

- Integration with Smart Systems: Charging systems that integrate with smart warehouse or facility management systems offer better monitoring and optimization of energy usage, enhancing overall efficiency.

- Innovative Charging Technologies: Look for features like fast charging, opportunity charging, or wireless charging solutions, which can reduce downtime and increase productivity.

Environmental Impact

When selecting an AGV battery charging system, understanding its environmental impact is essential. Here’s what to look out for:

- Energy Efficiency: Opt for systems that maximize energy efficiency, reducing overall power consumption and lowering operational costs.

- Eco-friendly Technologies: Consider chargers that use sustainable technologies or those that have a minimal ecological footprint to support your company’s green initiatives.

- Recyclability: Check the recyclability of the system components, including the batteries, to ensure they align with environmental conservation efforts.

Vendor Support and Warranty

The reliability of vendor support and the comprehensiveness of warranty coverage are significant when investing in an AGV charging system. Key aspects include:

- Vendor Reputation: Choose a vendor known for reliable support and robust solutions. Check their service history and customer feedback.

- Warranty Terms: Examine the warranty terms closely. Look for warranties that cover extended periods and include comprehensive support.

- Technical Assistance: Ensure that the vendor offers timely technical support. Availability of spare parts and the ability to quickly address technical issues are crucial for minimizing downtime.

Tlpower is a trusted manufacturer of AGV battery charging systems, vital for transforming material handling and industrial operations. Our bespoke power solutions cater to both lead-acid and lithium-ion batteries, ensuring maximum productivity, efficiency, and safety. Designed to operate in demanding conditions, Tlpower’s systems offer intelligent monitoring, diagnostics, and over-the-air connectivity for remote access and updates.

Rigorous testing guarantees reliability, with resistance to impact, vibration, thermal, and chemical stresses. Compact, lightweight designs enhance performance in harsh environments.

Through collaboration with industry leaders, Tlpower advances automated mobility, delivering cutting-edge, reliable, and eco-friendly solutions for the automated revolution.

Common Challenges and Solutions in AGV Charging

AGV systems face several challenges that can impact their efficiency and functionality. Understanding these challenges and their solutions is key to optimizing your AGV fleet’s performance.

- Integration Complexities: Integrating new charging systems with existing AGV setups can be daunting. Solution: Choose systems that offer flexible integration options and provide comprehensive technical support.

- Cost Issues: Initial setup and ongoing operation costs can be significant. Solution: Consider systems with scalable capabilities that allow gradual investment.

- Maintenance Requirements: Frequent maintenance can reduce system uptime. Solution: Opt for systems with robust design and minimal maintenance needs.

Energy Management and Optimization

Effective energy management strategies are essential for enhancing the efficiency and sustainability of AGV charging systems. Implementing advanced algorithms and considering energy storage solutions can lead to significant improvements.

Key Strategies:

- Peak Shaving: This technique involves reducing charge power during peak electricity usage times to lower energy costs.

- Demand Response: Participate in utility programs that incentivize energy usage reductions during high-demand periods.

- Energy Storage Solutions: Use battery storage systems to capture and utilize excess energy during off-peak hours for charging.

Maintenance and Safety in AGV Charging

Regular maintenance and adherence to safety protocols are crucial for the longevity and safe operation of AGV charging systems. Understanding and implementing these practices can prevent operational disruptions and ensure personnel safety.

Regular Maintenance Tasks:

- Inspection and Cleaning: Regularly inspect and clean charging contacts and stations to prevent power inefficiencies or electrical hazards.

- Software Updates: Keep the charging system software up-to-date to ensure compatibility and efficiency.

- Battery Health Checks: Monitor battery cycles and perform diagnostics to assess battery health and optimize charging strategies.

Safety Tips:

- Proper Training: Ensure that all personnel are trained on the safe operation and emergency procedures of AGV charging stations.

- Emergency Protocols: Establish and clearly mark emergency shutdown procedures and first-response protocols.

- Regular Audits: Conduct safety audits to identify and rectify potential hazards associated with AGV charging.

Regulatory Compliance and Standards

Engaging with regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the USA, or similar organizations worldwide, helps ensure that AGV charging installations comply with all relevant workplace safety regulations. Compliance with environmental regulations concerning battery disposal and recycling is also crucial for sustainable operations.

- Safety Certifications: Ensuring that AGV charging systems meet international safety standards like ISO 3691-4, which specifies requirements for driverless industrial trucks and their systems.

- Electrical Standards: Compliance with standards such as IEEE 1625 and IEEE 1725 for battery systems used in mobile applications ensures reliability and safety in operations.

- Interoperability Requirements: Adherence to interoperability standards ensures that AGV systems can operate seamlessly across different platforms and setups, enhancing flexibility in deployment.

Conclusion

When you need efficiency and low cost all in one, the AGV is up to the task as they are made for internal material transport.

Yes, you’ll experience difficulty trying to charge while driving, and that’s where battery charging management comes into place.

Choosing the right AGV charging system is an assignment that requires careful consideration. Ensure that whatever system you choose is capable of meeting the current operational demands of your industry.

相关推荐

- Forklift Charging: How to Charge a Forklift and Tips When Choosing a Forklift Battery Charging System

- What is Three Phase Power: Definition, Working Method and Applications

- Industrial Battery Charging: Methods, Best Practices and Safety Precautions

- Is There a Difference Between Industrial Batteries and Regular Consumer Batteries?

- What is an Industrial Battery: Definition, Types, Components & Applications

© 2025. All Rights Reserved. 琼ICP备88888888号