- 【Alltruth Limited】Welcome to Alltruth Power(www.alltruthpower.com), We provide you professional power solutions.

- Make a call:138 5726 9602

Industrial Battery Charging: Methods, Best Practices and Safety Precautions

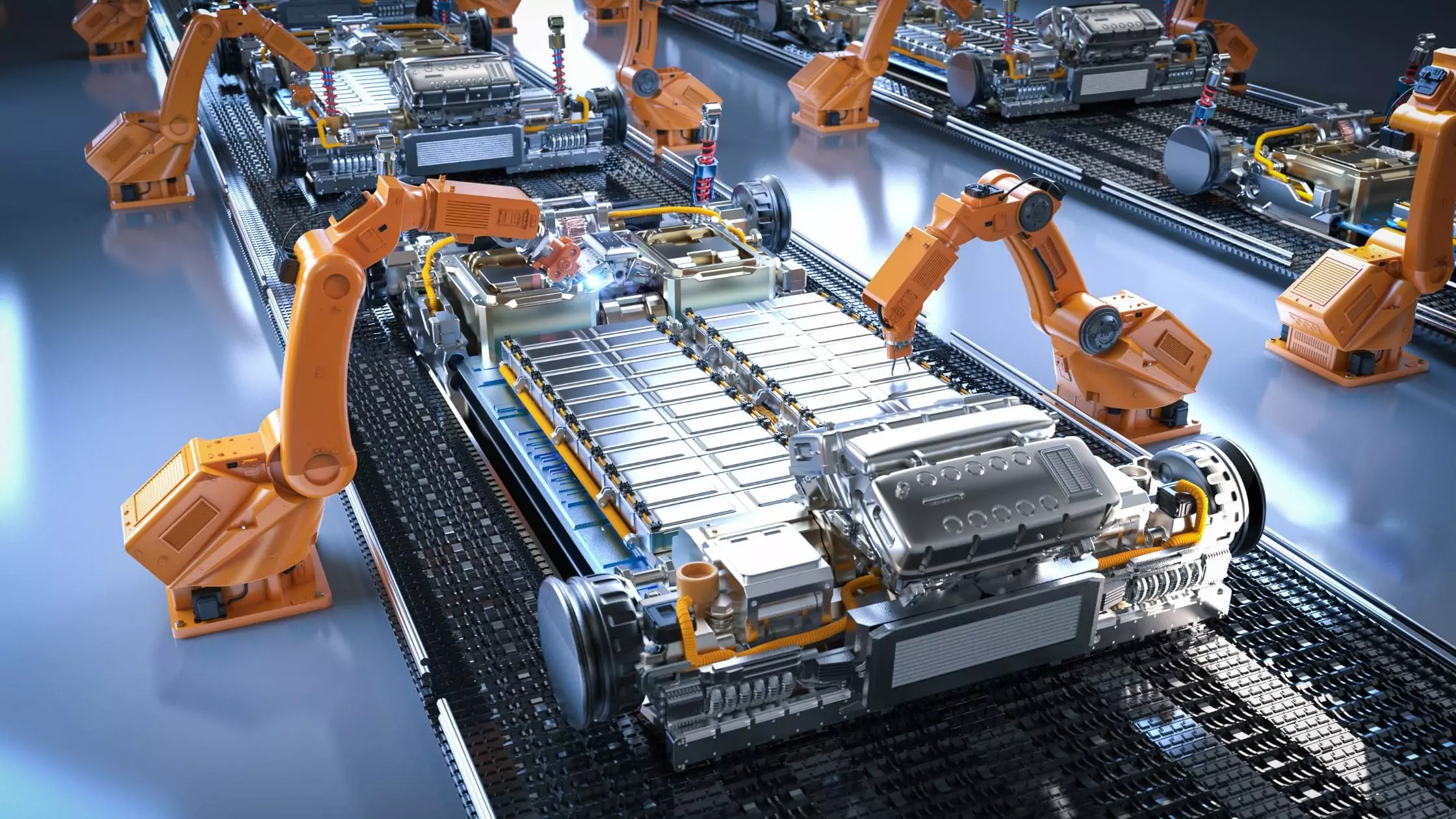

Industrial battery charging provides the know how that powers countless machines and vehicles in various industrial settings. This article explores the nuances of industrial battery charging, and what differentiates it from regular consumer battery charging.

Before delving deeper into the specifics of charging, it’s essential to understand what sets industrial batteries apart. Industrial batteries are designed for robustness and longevity, capable of enduring the rigorous demands of heavy machinery and extended operational hours.

These batteries are typically larger, have higher capacities, and come in various types, including lead-acid and lithium-ion, each with specific charging needs and applications.

What is the Difference Between Industrial Battery Charging and Charging Regular Consumer Batteries?

When you plug in your smartphone or laptop, you’re using a consumer battery charger, which is designed for small-scale batteries.

However, industrial battery charging operates on a whole different level.

Industrial battery charging involves systems that are capable of handling high demand and extended use typical to industrial environments. Unlike the chargers used for our personal gadgets, industrial chargers must manage larger batteries such as lead acid batteries and lithium ion batteries, commonly used in heavy machinery and transportation.

The key differences include:

- Scale and Capacity: Industrial batteries, like those in forklifts or manufacturing equipment, have much higher capacities measured in amp hours. They need chargers that can deliver much larger power outputs safely and efficiently.

- Charging Methods: Methods such as opportunity charging and conventional charging are unique to industrial settings. These methods consider factors like shift patterns and operational downtime, optimizing battery life and productivity.

- Endurance and Durability: Industrial batteries are built to endure harsh environments and repetitive use, which consumer batteries are not designed for. They also feature robust maintenance routines involving regular checks and balances to ensure safety and efficiency.

- Safety Standards: The safety precautions for industrial battery charging are stringent due to the higher risks involved. These include using personal protective equipment (PPE) and adhering to specific protocols to prevent accidents like fires or chemical spills.

Before going into the different industrial charging methods and best practices let’s first define what exactly an industrial battery charger is.

What is an Industrial Battery Charger?

An industrial battery charger is a device that controls battery charging in a wide range of industrial applications

What sets industrial chargers apart is their ability to regulate the charge according to the battery’s condition and the specific requirements of the application. Features like adjustable charge rates, multi-stage charging, and temperature compensation are common. Such capabilities are essential for applications involving forklifts, lift trucks, and other industrial vehicles, which rely on consistent and reliable battery power to operate.

Moreover, the importance of using the right charger, extends beyond merely charging the battery. It includes protecting the battery from overcharging, reducing downtime, and preventing safety hazards such as overheating or hydrogen gas build-up.

Each industrial battery charger is designed to meet specific industrial standards, ensuring that every charging cycle contributes to an extended battery life and efficient energy use, crucial for maintaining the productivity and efficiency of industrial operations. By choosing the appropriate industrial battery charger, companies can save on costs, enhance safety, and ensure their machinery operates without interruption.

What are The Different Industrial Battery Charging Methods?

Understanding the various methods for charging industrial batteries is crucial for ensuring efficiency and prolonging the lifespan of the batteries used in heavy machinery and other industrial applications. These methods are tailored to meet the unique demands of industrial operations, providing different benefits and facing distinct challenges.

Conventional Charging

Conventional Charging is one of the most traditional methods used in industrial settings. This technique involves charging the battery after a shift, utilizing a low current for about 8 to 10 hours to achieve a full charge. Following the charging period, there is typically a cooling phase of 6 to 8 hours before the battery can be used again. This method is often implemented overnight, making it suitable for operations that can afford downtime outside of regular working hours.

Pros of Conventional Charging

- Maximizes Battery Health: By charging at a lower current, the battery is less likely to suffer from heat buildup and stress, which can degrade its components over time.

- Enhances Battery Longevity: This method contributes to longer battery life by avoiding the stress of fast charging cycles.

Cons of Conventional Charging

- Longer Charging Time: Requires significant downtime for both charging and cooling, which may not be feasible for multi-shift operations.

- Operational Limitations: Not ideal for facilities that operate around the clock unless multiple batteries are available to rotate through as one charges.

Best For

Facilities with single-shift operations that do not require immediate reuse of batteries and can accommodate overnight charging.

Charging Time and Rate

Typically involves charging at rates around 10-15 amps for lead acid batteries, taking about 8-10 hours to fully charge a battery, depending on its capacity in amp hours.

Opportunity Charging (OC)

Opportunity Charging (OC) represents a strategic approach to maintaining industrial batteries, especially in environments requiring high uptime. This method allows batteries to be charged briefly and frequently during short breaks or downtime, which can be crucial in multi-shift operations where equipment like forklifts are in constant use.

- Initiation: Charging typically begins when the battery’s charge level drops to about 25%.

- Duration: The process lasts between 4 to 6 hours, allowing the battery to reach an adequate charge to continue operations until the next opportune charging time.

- Methodology: Similar in theory to fast charging, OC uses moderate currents to quickly bring the battery up to a functional state without fully charging it, preventing downtime and boosting productivity.

Pros of Opportunity Charging

- Reduces Downtime: By charging batteries during short breaks, OC minimizes the impact on operational workflow, keeping machines running without long pauses.

- Enhances Productivity: Frequent, short charges ensure that equipment is ready to use when needed, supporting continuous operation.

- Eliminates Need for Multiple Batteries: There’s no need to invest in numerous batteries per machine, as OC allows for quick recharges that fit within standard operational breaks.

Cons of Opportunity Charging

- Increased Wear and Tear: Frequent charging can accelerate the degradation of battery health, reducing its overall lifespan.

- Maintenance Requirements: Batteries require weekly equalizing charges to prevent sulfation and maintain battery efficiency, adding to maintenance tasks.

Best For

- Multi-Shift Operations: Ideal for facilities that operate around the clock and cannot afford long charging interruptions.

- High-Demand Environments: Particularly effective in settings where equipment usage is constant and operational efficiency is critical.

Charging Time and Rate

Charging typically occurs at a rate adjusted to the battery’s capacity, often around 20 to 40 amps per 100 amp hours, depending on the specific battery and charger configuration. This allows the battery to rapidly reach a charge level that supports continued operation without reaching full capacity, balancing immediate usage needs with long-term battery health.

Fast Charging (FC)

Fast Charging (FC) is a method designed to minimize downtime in high-demand environments where industrial batteries are essential for continuous operation. Unlike traditional charging methods that may take hours, FC substantially speeds up the process, allowing batteries to be recharged rapidly during shorter breaks or between shifts.

- Initiation: Fast Charging typically begins when the battery’s charge level falls to around 40%.

- Duration: This method is capable of charging batteries in 2 hours or less, making it suitable for quick turnarounds.

- Currents Used: FC utilizes currents of approximately 30 to 60 amps per 100 amp hours, a significant increase over the currents used in opportunity charging or conventional methods.

Pros of Fast Charging

- Reduces Downtime: By charging batteries quickly, FC maximizes operational efficiency, ensuring that machines are ready to go without long waits.

- Enhances Productivity: With less time spent charging, more time can be devoted to productive work, particularly crucial in multi-shift operations where equipment use is nearly constant.

- No Need for Multiple Batteries: The quick charge rate eliminates the need for numerous batteries per machine, as one can be used almost continuously with short, fast recharges.

Cons of Fast Charging

- Battery Lifespan: The intense influx of power can stress the battery, potentially shortening its overall lifespan compared to batteries charged at slower rates.

- Maintenance Needs: Fast charging batteries typically require more frequent equalizing charges to counteract sulfation, adding to maintenance schedules.

- Heat Production: The rapid charging process generates significant heat, which can be harmful to battery components and may necessitate additional cooling measures.

Best For

- Continuous and Multi-Shift Operations: Ideal for industries where equipment needs to be available 24/7 without significant pauses for charging.

- High-Demand Situations: Particularly effective in settings where downtime can lead to substantial disruptions in workflow and productivity.

Charging Time and Rate

Fast charging processes involve quick bursts of high current, significantly cutting down the time it takes to bring a battery up to a usable charge level. The exact rate can vary depending on the battery’s capacity and the specific requirements of the operation, but typically, it ranges as mentioned earlier.

Constant Voltage Charging

Constant Voltage Charging is a prevalent method in the maintenance of industrial batteries, particularly for ensuring the longevity and stability of the battery’s charge state. This method involves maintaining a nearly constant voltage supply to the battery throughout the charging cycle while allowing the current to decrease as the battery approaches full charge.

- Process: The charger applies a steady voltage, typically specific to the battery type, such as lead acid or lithium ion. For lead acid batteries, this might be around 2.40 to 2.45 volts per cell.

- Duration: The charging time can vary based on the battery’s discharge state and capacity but generally takes longer than fast charging methods, ensuring a thorough and deep charge.

Pros of Constant Voltage Charging

- Prevents Overcharging: Maintaining a constant voltage helps prevent the battery from being overcharged, which can reduce battery life.

- Enhances Battery Efficiency: By allowing full saturation, this method can help restore the full active material necessary for the battery’s optimum performance.

Cons of Constant Voltage Charging

- Longer Charging Time: Requires more time to achieve a full charge, which may not be ideal for operations requiring quick battery turnover.

- Monitoring Required: To avoid the potential for overcharging, careful monitoring is necessary, especially towards the end of the charging cycle.

Best For

- Applications where battery longevity and health are more critical than immediate availability.

- Settings where batteries can be charged overnight or during off-peak hours without disrupting operational efficiency.

Charging Time and Rate

Depending on the battery’s capacity and initial state of discharge, constant voltage charging might typically require about 8-12 hours to reach a full charge, employing a gradually decreasing current as the charge completes.

Constant Current Charging

Constant Current Charging is another fundamental method used in various industrial settings. This approach involves charging the battery at a consistent current irrespective of the changing voltage as the battery charges up.

- Process: A fixed current is passed through the battery, and as the battery’s internal resistance rises, the voltage incrementally increases until the set cut-off point.

- Duration: This method can charge batteries relatively quickly depending on the set current and the battery’s total capacity.

Pros of Constant Current Charging

- Quick Charge Capability: Ideal for situations where rapid charging is needed, as it can replenish battery charge swiftly.

- Simplicity and Control: Easier to control and implement in automated processes due to its straightforward nature.

Cons of Constant Current Charging

- Risk of Overcharging: If not properly monitored or if the cut-off voltage is not adequately set, there is a risk of overcharging the battery, which can lead to reduced battery life and potential safety hazards.

- Heat Generation: Higher currents used in this method can generate significant heat, requiring effective cooling systems to prevent battery damage.

Best For

- High-demand environments where equipment needs quick recharging to maintain continuous operation.

- Operations that can systematically monitor and control charging processes to prevent overcharging.

Charging Time and Rate

The time required for a full charge can range from 1 to 4 hours, depending on the battery’s capacity and the current used, which might typically be about 10 to 40 amps, depending on the specific requirements and battery specifications.

Float Charging

Float Charging is a battery charging technique primarily used to maintain a full charge level in a battery while minimizing the risk of overcharging, which is crucial for prolonging battery life. This method involves applying a constant voltage lower than the battery’s maximum charge voltage to maintain the battery without additional charging cycles.

- Process: Once the battery reaches full charge, the charger switches to a lower voltage, typically around 13.2 to 13.8 volts for a 12-volt lead acid battery, to sustain the charge indefinitely without degrading the battery.

- Duration: Float charging can be sustained for extended periods, essentially indefinitely, as it only compensates for the battery’s natural discharge.

Pros of Float Charging

- Prolongs Battery Life: By maintaining an optimal charge state and avoiding overcharging, float charging helps extend the battery’s lifespan.

- Continuous Readiness: Keeps batteries at full charge without requiring frequent recharging cycles, ensuring they are always ready for use.

Cons of Float Charging

- Lower Energy Efficiency: Continuous charging, even at low rates, can lead to energy waste over time if not monitored properly.

- Maintenance Oversight: Requires regular checks to ensure the system is functioning correctly and not leading to undercharging or battery sulfation.

Best For

- Standby or backup power systems where batteries must remain fully charged and ready for immediate use, such as in UPS systems or emergency lighting.

Charging Time and Rate

Slightly lower than the battery’s discharge rate, usually set to maintain the battery at its full charge without overcharging. This is commonly around 13.2 to 13.8 volts for a 12-volt lead acid battery.

Pulse Charging

Pulse Charging is an advanced method that enhances battery life and performance by intermittently delivering bursts of charge followed by rest periods, allowing the electrolyte within the battery to stabilize.

- Process: This method alternates between charging phases with high current pulses and rest phases without current. It’s often automated to respond to the battery’s current state and adaptively adjust the pulse strength and duration.

- Duration: The total charging time can vary, but pulse sequences are typically designed to optimize charging efficiency and may range from several minutes to several hours, depending on the battery capacity and state of discharge.

Pros of Pulse Charging

- Reduces Battery Stress: By allowing the battery to rest between pulses, this method minimizes heat build-up and potential damage to the battery cells.

- Improves Battery Health: Can help break down sulfation in lead-acid battery plates, which is common in batteries that have been undercharged or left discharged for prolonged periods.

Cons of Pulse Charging

- Complex Technology: Requires more sophisticated charging equipment and control systems, which can increase the cost.

- Specific Applications: Not suitable for all battery types, and its effectiveness can vary based on the battery’s chemistry and condition.

Best For

- Batteries that require frequent recharging cycles, such as those used in electric vehicles or frequent-start machinery, where battery health is crucial to operational efficiency.

Charging Time and Rate

Specific to the battery’s condition and capacity, pulse charging might deliver bursts of 100 amps for short durations (seconds to minutes), tailored to not overcharge the battery but refresh it efficiently.

Trickle Charging

Trickle Charging is a method used to maintain the charge of a battery at full capacity by applying a continuous, small current. This approach is common in maintaining the readiness of batteries in systems where sudden power requirements are expected.

- Process: Trickle charging involves the application of a constant, low current, typically set just above the natural discharge rate of the battery.

- Duration: The charging rate is very low, typically just above the self-discharge rate, often around 1-2 amps for large industrial batteries. This allows the battery to stay at full charge without overcharging.

Pros of Trickle Charging

- Battery Longevity: Constantly maintains the battery at full charge, preventing the harmful effects of a full discharge.

- Readiness: Ensures that the battery is always ready for immediate use, which is critical in applications such as emergency backup systems.

Cons of Trickle Charging

- Energy Consumption: Although the current is minimal, the long-term energy use can accumulate, especially when maintaining multiple batteries.

- Monitoring Required: Requires ongoing monitoring to prevent potential overcharging if the system fails to automatically adjust to changing battery conditions.

Best For

This method is best for emergency systems, standby power systems, and other applications where batteries must remain fully charged and ready for immediate deployment.

Charging Time and Rate

The charge rate is generally low, around 1 to 2 amps, and is continuous to keep the battery topped off without causing overcharging.

What are Important Practical Tips for Industrial Battery Charging?

When it comes to charging industrial batteries, it’s crucial to adopt best practices to enhance battery life and ensure safety in industrial environments. Here are our twelve tips on effectively charging industrial batteries:

- Charge Based on Need: Initiate the charging process only when the battery’s charge level drops below 30%. This approach contrasts with time-based charging schedules, which can lead to reduced battery efficiency and lifespan.

- Avoid Overcharging and Undercharging: To maximize battery life, avoid both overcharging and undercharging. Overcharging can lead to excessive heat and battery damage, while undercharging may not provide sufficient power for operations.

- Set Up a Dedicated Charging Area: Establish a specific area for battery charging. This area should be well-ventilated, free from flammable materials, and equipped with appropriate charging equipment to handle the specific needs of industrial batteries.

- Ensure Compatibility of Charger and Battery: Use a charger that matches the battery specifications, particularly regarding output voltage and ampere-hour (AH) rating. The charger’s output voltage should align with the battery’s voltage requirements, and its AH rating should be within 10% of the battery’s capacity.

- Inspect and Maintain Charging Equipment: Regularly inspect charger cables and connectors for wear and tear. Ensure that all connections are secure and free from damage to maintain efficient charging and reduce the risk of electrical hazards.

- Maintain Charging Records: Keep a log of all charging sessions, including duration and frequency. These records are essential for warranty purposes and help in assessing the battery’s performance over time.

- Implement Controlled Charging Cycles: Limit the number of complete charge cycles. Most industrial batteries are designed to handle a specific number of complete charge cycles before their efficiency starts to decline.

- Provide Sufficient Charging Time: Allow the battery to charge fully, typically requiring around eight hours, to ensure that the charge is evenly distributed across all cells.

- Perform Regular Equalizing Charges: Conduct an equalizing charge at least once a week. This process rebalances the battery cells and corrects imbalances in the electrolyte levels.

- Water the Batteries After Charging: Once the battery is fully charged and has cooled down, check and refill the water levels. This helps in maintaining the electrolyte levels and ensures proper battery maintenance.

- Monitor for Signs of Distress: Watch for excessive heating, unusual smells, or leaking fluids from the battery. These signs could indicate that the battery needs maintenance or replacement.

- Train Your Staff: Ensure that all personnel involved in battery maintenance and charging are properly trained in handling and safety procedures to minimize risks and enhance operational efficiency.

More Useful Advices

As we delve into more detailed practices for charging industrial batteries, it’s crucial to adopt strategies that not only enhance efficiency and safety but also anticipate future needs and changes. Here are eight best practices that redefine how industrial batteries should be managed:

- Calculate Your Truck’s AH per Hour Usage:

Purpose: Understanding the ampere-hour (AH) usage helps avoid battery oversizing and under-sizing, which can lead to overheating or insufficient charge.

Method: Utilize data loggers to monitor AH usage, which offers insights into efficient battery usage throughout the day.

Duration: Experts recommend logging data for at least three weeks to capture a comprehensive usage pattern, which helps in strategic planning of charging cycles.

- Future-Proof Battery Sizing

Strategy: As your business evolves, so should your battery management strategies. Prepare for future changes like operational expansion or new technological integrations.

Consideration: Adjustments might include modifying battery sizes or charging schedules based on new workflows or additional equipment.

- Safety First: The Stop Button Protocol

Importance: Always ensure that the stop button on chargers is fully engaged before and after charging to prevent arcing and other electrical hazards.

Checklist: Regularly inspect and clean contacts and ensure proper sizing and condition of cables and connectors.

- Adapt to Workday Variations

Observation: Changing workday structures, like task-based operations, can affect battery usage.

Adaptation: Be flexible in charging strategies to accommodate earlier or later starts based on daily operational demands.

- Clear, Direct Charging Instructions

Implementation: Post simple, straightforward instructions near charging stations to avoid common mistakes.

Multilingual: Consider multilingual displays to cater to diverse workforces, ensuring that all employees understand the charging protocols.

- Optimal Charger Location

Update: Transition from traditional lunchroom charging stations to Point-Of-Use Charging setups, which allow for charging during operational downtimes, ensuring that batteries are adequately charged throughout the day.

- Regular Maintenance and Inspection

Routine: Incorporate regular checks of the battery’s water levels, particularly after charging, to ensure optimal performance and prolong battery life.

Special Attention: Schedule detailed inspections of the battery and its connections monthly to preempt any potential issues.

- Educational Outreach

Training: Provide ongoing training and updates for all personnel involved in battery maintenance and charging.

Resources: Offer resources and access to quick-guidance tools that reinforce best practices and troubleshooting methods.

What are Important Safety Measures to Take Before and During Industrial Battery Charging?

Ensuring safety during the charging of industrial batteries is paramount. The following best practices provide essential guidelines to prevent accidents and prolong the life of the batteries:

- Wear Appropriate Personal Protective Equipment (PPE): Handling batteries without protective gear can expose workers to chemical burns from battery acid and electrical shocks. Safety glasses, acid-resistant gloves, and face shields are essential when handling batteries, especially during connections and disconnections.

- Verify Charger Compatibility: Using a charger that matches the battery’s specifications ensures efficient charging and prevents damage. Always check the output voltage and ampere hour (AH) rating to ensure they align with the battery’s requirements.

- Maintain a Clean and Ventilated Charging Area: Adequate ventilation reduces the risk of hydrogen gas build-up, which can lead to explosions. Ensure charging stations are away from heavily trafficked areas and have sufficient air flow.

- Regular Inspection of Charging Equipment: Faulty equipment can lead to inefficiencies and hazards, including electrical fires and battery failures. Inspect cables and connectors for signs of wear or damage before each use and replace any faulty components immediately.

- Follow Correct Charging Procedures: Incorrect charging can lead to overcharging or undercharging, both of which can damage the battery and reduce its lifespan. Charge according to the manufacturer’s instructions and ensure batteries are charged within the recommended SOC (State of Charge) range, typically between 30% to 70%.

- Monitor Charging Progress: Continuous monitoring helps prevent overcharging, which can cause overheating and increase wear on the battery. Use timers or advanced battery management systems that automatically stop charging when the battery is full.

- Establish and Enforce Safety Protocols: Clear protocols help prevent accidents and ensure that all personnel adhere to safety standards. Include regular safety training and clear, visible instructions near all charging stations.

- Perform Regular Battery Maintenance: Routine maintenance ensures batteries operate safely and efficiently. Check water levels after charging cycles, clean battery tops to remove dust and debris, and equalize charge regularly to balance cell voltages.

What Are the Most Common Mistakes in Industrial Battery Charging?

Charging industrial batteries seems straightforward, but several common mistakes can compromise the efficiency and lifespan of your batteries. Recognizing and avoiding these errors is crucial for maintaining optimal battery performance and safety. Here’s what you need to watch out for:

- Overcharging the Battery: Frequently leads to excessive heat and stress, reducing battery life. Use a smart charger that automatically stops when the battery is fully charged. Ensure your charger settings align with the battery’s specifications.

- Undercharging: Consistently failing to fully charge batteries can cause sulfation, which may permanently reduce the battery’s capacity. Always complete the charging cycle before disconnecting the battery. Consider using opportunity chargers for top-ups during breaks if full cycles are impractical.

- Ignoring Battery Temperature: Charging batteries that are too hot or too cold can lead to poor performance and degradation. Allow the battery to reach room temperature before charging. If batteries are frequently too hot after use, check the vehicle’s workload and operating conditions.

- Using Mismatched Chargers and Batteries: Chargers that don’t fit the battery’s voltage or amp-hour specifications can lead to improper charging. Verify that the charger matches the battery’s specifications. Consult with your supplier to ensure compatibility.

- Failing to Train Staff on Proper Charging Techniques: Untrained staff may mishandle batteries, leading to accidents or reduced battery life. Provide thorough training on the correct charging process, handling emergencies, and daily maintenance practices.

- Disregarding the Battery’s State of Charge (SOC): Charging the battery too often or only after deep discharges affects its performance and longevity. Use battery monitoring tools to maintain an optimal SOC range, generally between 30% and 70%, ensuring batteries are neither depleted nor overcharged frequently.

How to Choose the Right Industrial Battery Charger for Your Application?

Selecting the right industrial battery charger is critical for maintaining battery efficiency and longevity. Making an informed choice can save costs and improve productivity by ensuring your batteries are charged optimally. Here are key factors to consider, and for a detailed guide, check how to choose an industrial battery charger.

- Battery Compatibility: Ensure the charger is compatible with your battery type, whether it’s lead-acid, lithium-ion, or another type. Match the charger’s output voltage with your battery’s voltage specifications. The charger should suit the battery’s capacity to provide efficient charging without overloading.

- Charging Speed: Consider whether you need a standard charger or a fast charger based on operational downtime and shift patterns. Adjustable rates can help optimize charging for different states of battery depletion.

- Environmental Conditions: Some chargers are better suited for extreme conditions, important in environments like cold storage or outdoor operations. Adequate air circulation is crucial to prevent overheating and ensure safety.

- Size and Portability:The physical size of the charger should fit within your designated charging area. Consider whether the charger needs to be stationary or if a portable option is required.

- Advanced Features: Features such as automatic voltage adjustment and discharge monitoring can enhance battery life and performance. Some modern chargers offer connectivity for monitoring and control via mobile devices or computers.

- Safety Features: Look for chargers with built-in safety features like overcharge protection, temperature control, and spark-free connectors. Ensure the charger meets industry safety standards and certifications pertinent to your region or sector.

Conclusion

Proper industrial battery charging maximizes battery lifespan, reduce the risk of overheating and accidents, and maintain reliable power for heavy machinery. By following established guidelines and safety measures, manufacturers and industries can enhance productivity, prevent costly downtime, and protect their investments in battery technology.

Ensuring that staff are well-trained and equipment is properly maintained further reinforces these benefits. Strict adherence to charging protocols is vital for ensuring both the efficiency and safety of industrial battery operations.

相关推荐

- Forklift Charging: How to Charge a Forklift and Tips When Choosing a Forklift Battery Charging System

- How to Charge Automated Guided Vehicle: Charging AGV Guide

- What is Three Phase Power: Definition, Working Method and Applications

- Is There a Difference Between Industrial Batteries and Regular Consumer Batteries?

- What is an Industrial Battery: Definition, Types, Components & Applications

© 2025. All Rights Reserved. 琼ICP备88888888号