- 【Alltruth Limited】Welcome to Alltruth Power(www.alltruthpower.com), We provide you professional power solutions.

- Make a call:138 5726 9602

Three-phase power stands out as a pivotal concept, especially in industrial and commercial applications. But what exactly is three-phase power?

Before diving into the details, it’s important to understand this fundamental electrical scheme that significantly enhances the efficiency of power distribution.

Three-phase power, in its essence, is a method of alternating current (AC) power generation, transmission, and distribution that involves three currents or phases that are offset in time to ensure a constant power supply.

This method is preferred for its reliability and efficiency, especially in powering large motors and heavy loads.

What Electrical Phase Means

The term ‘phase’ refers to the characteristic of the voltage and current, specifically in how they are expressed in an alternating current (AC) cycle.

Essentially, a phase in an electrical context denotes the timing and magnitude of electricity as it flows through a circuit.

Each phase is typically represented by a sine wave in AC systems, and the synchronization of these phases determines the efficiency and stability of the power supply.

Differences Between Phase in Electricity and in Other Contexts

The concept of phase extends beyond electricity; it is used in various fields to describe cycles and stages of progression. However, in electrical engineering, phase specifically pertains to the distribution and timing of electrical currents within a power system. Understanding this distinction is crucial for effectively managing and implementing power systems, whether they are for residential, commercial, or industrial applications.

Single-Phase Power Explained

Single-phase power is a type of electrical power distribution commonly used in residential homes and small businesses.

It involves the use of a single sine wave of AC and is characterized by having one live wire and one neutral wire.

The voltage in a single-phase system typically varies in a uniform pattern, providing a stable and straightforward power supply suitable for lighter loads.

Common Applications and Limitations

Single-phase power is widely used due to its simplicity and cost-effectiveness in applications where high power density is not required. It powers most household appliances, lighting, and heating systems. However, its limitations become apparent in industrial settings where larger machinery requires more robust power solutions.

This is where three-phase power systems come into play, offering greater power capacity and efficiency for heavy-duty applications.

Each phase in a three-phase system carries power at a consistent maximum, which balances the load and minimizes energy loss, making it ideal for powering large motors and other heavy equipment.

In contrast, single-phase power can experience dips and surges, which may not be suitable for all types of machinery and can lead to inefficiencies and increased wear.

This transition from discussing single-phase to three-phase power illustrates how different applications necessitate specific types of electrical setups to efficiently meet their power needs. Understanding these distinctions and applications ensures that the right type of power is utilized for the right application, maximizing efficiency and reducing operational costs.

How Does Three-Phase Power Work?

Three-phase power utilizes a system of three alternating currents that are uniformly separated in phase angle, ensuring a continuous energy flow with minimal fluctuations in voltage and current.

Each phase in this system operates with a common frequency and amplitude but is offset by one-third of a cycle from the others.

This unique arrangement allows for consistent power delivery and efficient electricity usage, particularly in high-demand settings.

In technical terms, the three-phase system employs a polyphase system of alternating currents where each phase delivers power in succession, reducing the need for large conductor sizes and providing power that is more stable and less prone to dips than single-phase power systems.

The Concept of Alternating Current in Three-Phase Systems

Alternating current (AC) is fundamental to the functionality of three-phase systems. In such systems, the AC flows in three separate phase wires, each phase shifting at 120 degrees to the others.

This phase shift is crucial as it allows for the three-phase system to provide a more constant power level than possible with a single-phase power supply.

The nature of alternating current in this setup not only maximizes efficiency but also enhances the power system’s capacity to handle heavy loads without significant energy loss, as the load is evenly distributed across the three phases.

Why Three-Phase Power?

Three-phase power is predominantly used in commercial and industrial environments due to its inherent advantages over single-phase power systems. The primary reasons for its widespread use include:

- Efficiency: Three-phase power systems are significantly more efficient at transmitting power, which is especially beneficial for equipment requiring a large amount of power, such as industrial motors and large electrical machinery. This efficiency stems from the continuous power generation capability of three-phase systems, which ensures that power peaks are more spread out and energy delivery is steadier.

- Stability and Load Balance: The phase separation in three-phase systems allows for a nearly constant power output. This balance is crucial in settings where machinery must operate continuously without interruptions or power sags, common in single-phase systems.

- Cost-Effectiveness in Power Transmission: When transmitting power over long distances, three-phase systems are more cost-effective. They require less conductor material for the same amount of power transmission as compared to single-phase systems, resulting in lower overall infrastructure costs.

- Enhanced Equipment Lifespan: Equipment running on three-phase power experiences less stress due to the smoother operation provided by the balanced power supply. This can lead to extended machinery life and reduced maintenance costs.

The Historical Development of Three-Phase Power

The genesis of three-phase power can be traced back to the late 19th century, marked by the pioneering work of Nikola Tesla, a name synonymous with the invention and development of the alternating current (AC) supply system.

Tesla’s patents in 1888, particularly for the polyphase system, laid the groundwork for the practical deployment of three-phase power.

His work facilitated efficient generation, transmission, and utilization of electrical energy across great distances, revolutionizing the electrical industry.

Simultaneously, Mikhail Dolivo-Dobrovolsky, working in Europe, developed the first three-phase electric generator and motor in 1891. His innovations included the introduction of the three-phase transmission system and the cage-rotor induction motor, both fundamental to the widespread adoption of three-phase power in industrial applications.

Evolution of Three-Phase Power Technology

From its inception, three-phase power technology has evolved significantly, driven by continuous advancements and a growing understanding of electrical engineering principles.

In the early 20th century, the expansion of electrical grids and the establishment of standardized voltages and frequencies contributed to the broader implementation of three-phase systems.

This period witnessed the transformation of industrial power, with three-phase systems becoming the backbone of modern manufacturing and production industries.

By the mid-20th century, innovations such as silicon-controlled rectifiers and other power electronic devices further enhanced the functionality and efficiency of three-phase power systems.

These developments facilitated the precise control of power and the integration of renewable energy sources, like wind and solar, into existing electrical grids.

Moreover, the late 20th and early 21st centuries saw the introduction of digital technologies, smart grids, and advanced monitoring systems, which significantly improved the reliability, efficiency, and safety of three-phase power distribution networks.

Three-phase power continues to be integral to power distribution systems worldwide, driving the engines of industry and innovation.

What are Technical Aspects of Three-Phase Power?

Understanding these terms is crucial for anyone working with or studying three-phase electrical systems as they describe the fundamental components and functionalities.

- Phase Power: Refers to the division of electricity among three phases that collectively maintain a continuous rate of energy supply with a balanced load.

- Phase Wire: Each of the three wires in a three-phase system, conducting one phase of the cycle.

- Alternating Current (AC): Electrical current that reverses direction periodically, as used in three-phase systems.

- Phase System: The arrangement of phases in a circuit, which can be in a star (wye) or delta configuration.

- Phase Conductor: The conductor carrying the current in one phase of a three-phase system.

Phase Sequence and Its Importance

Phase sequence, or the order in which the phases reach their maximum values, is critical in three-phase systems. It determines the direction of rotation of three-phase motors, which is essential for applications where motor direction affects operational processes.

Incorrect phase sequence can cause motors to run in reverse, potentially leading to damage or operational failures. Ensuring the correct phase sequence is maintained during installation and maintenance is vital for the safety and efficiency of three-phase systems.

Balanced vs. Unbalanced Circuits

- Balanced Loads: In a three-phase system, a balanced load occurs when the power is equally distributed across all three phases, leading to optimal efficiency and minimized stress on the power supply system.

- Unbalanced Loads: Occur when one or more phases in a three-phase system draw more power than others. This can lead to inefficiencies, increased power losses, and potential overloads, which might damage the electrical system.

Balanced circuits are ideal in three-phase systems because they ensure the stability and longevity of motors and other electrical components. Conversely, monitoring and correcting unbalanced circuits is crucial to prevent the adverse effects associated with phase imbalance.

How Three-Phase Power is Generated and Distributed

Three-phase power generation involves producing electricity through methods that ensure three alternating currents are slightly out of phase with each other by exactly one-third of a cycle. This phase difference is crucial because it allows for a more consistent energy flow and reduces the total amount of wire needed for transmission compared to single-phase power.

Types of Connections in Three-Phase Systems

In three-phase systems, there are primarily two types of connections: Wye (Y) and Delta (Δ). Each configuration serves different purposes and exhibits unique characteristics:

- Wye (Y) Configuration: In a Wye configuration, all phase conductors are connected at a single neutral point, forming a path for current to return. This setup allows for the use of both line and phase voltages to power loads, making it versatile for various applications.

- Delta (Δ) Configuration: Delta configurations link each phase to two other phases, forming a closed loop that circulates current. This type of connection typically supports higher power transmissions and is used extensively in industrial environments where large machinery operates.

Generation Process and Distribution Mechanisms

- Generation Techniques:

- Rotating Generators: Utilize magnetic induction principles facilitated by rotating a conductor through a magnetic field to generate alternating current.

- Turbine Driven: Often driven by steam, gas, or hydro turbines, these generators are common in large power plants.

- Distribution Systems:

- Primary Distribution: Transfers high voltage power from plants to substations via transmission lines.

- Secondary Distribution: Involves reducing the voltage using transformers at substations for safe delivery to commercial or residential users.

Circuits and Loads in Three-Phase Systems

This section explores the essential components and configurations of circuits and loads in three-phase systems, vital for supporting robust and efficient power distribution in various applications.

We will dive into the operational nuances of three-wire and four-wire circuits, discuss the techniques for integrating single-phase loads into three-phase systems, and highlight best practices for managing three-phase loads effectively.

Understanding Three-Wire and Four-Wire Circuits

Differences and Applications:

- Three-Wire Systems: Predominantly used in three-phase systems without a neutral wire, three-wire configurations are common in high-power industrial settings where balanced loads are prevalent. This setup reduces the need for additional conductor material, making it cost-effective and reducing the complexity of the wiring system.

- Four-Wire Systems: Incorporating a neutral wire, four-wire systems are essential in scenarios where both single-phase and three-phase loads are present. The neutral wire provides a path for current in unbalanced loads and is crucial in residential and commercial buildings for safely managing discrepancies in phase loads.

The choice between these systems depends on the specific requirements of the power distribution network, considering factors like load balance, safety requirements, and economic efficiency.

Handling Single-Phase Loads on a Three-Phase System

Techniques for Connection and Management:

Connecting single-phase loads to a three-phase system requires careful consideration to maintain balance and ensure efficient operation. Techniques include:

- Distributing Loads Evenly: To prevent system imbalance, it’s crucial to distribute single-phase loads evenly across the three phases.

- Using Phase Converters: For devices strictly requiring single-phase power, phase converters can be used to transform three-phase power into single-phase power, ensuring compatibility and extending the usability of three-phase systems.

These strategies help mitigate the risk of overloading any single phase, thus maintaining system integrity and prolonging the lifespan of the electrical infrastructure.

Managing Three-Phase Loads

Best Practices for Connecting and Optimizing Loads:

Effective management of three-phase loads involves several best practices that enhance the performance and reliability of the power system:

- Balancing the Load: Ensure that large three-phase loads are evenly distributed across all three phases to prevent phase imbalance and reduce the stress on the electrical network.

- Regular Monitoring and Maintenance: Implementing routine checks and maintenance on three-phase systems helps identify potential issues early, preventing costly downtime and repairs.

- Utilizing Protective Devices: The use of protective devices, such as circuit breakers and overload relays, is vital in safeguarding against potential overloads or faults within the system.

Phase Converters: Bridging Single-Phase and Three-Phase Power

Phase converters are essential devices that enable the transformation of electrical power from one phase system to another, typically from single-phase to three-phase, allowing for efficient operation of three-phase machinery where only single-phase power sources are available. The main types of phase converters include:

- Rotary Phase Converters: These devices use a motor-generator setup to convert single-phase electricity into three-phase power, ideal for heavy, consistent loads.

- Static Phase Converters: Using capacitors, these converters start three-phase motors running on single-phase power but do not maintain three-phase power throughout operation, best suited for light to medium loads.

- Digital Phase Converters: Employing advanced electronic controls to generate three-phase power from a single-phase line, digital converters provide reliable and balanced power, suitable for precision and sensitive equipment.

Understanding the appropriate application for each type of converter ensures optimal equipment performance and longevity, reducing operational costs and energy consumption.

When and Why to Use Them

Phase converters are utilized primarily in environments where three-phase power is not available but required for specific equipment, typically in rural or older industrial areas. Key reasons for using phase converters include:

- Cost Efficiency: Installing a phase converter is generally less expensive than upgrading an existing single-phase system to a three-phase system.

- Flexibility: Allows the use of three-phase equipment in locations with only single-phase power, expanding the usability of heavy-duty machinery without significant infrastructural changes.

- Enhanced Power Capacity: Three-phase power is more efficient for running large motors and heavy loads, reducing wear and tear and enhancing performance.

Maintenance and Testing of Three-Phase Systems

Regular testing and maintenance of three-phase systems are crucial to ensure uninterrupted service and prevent costly downtime. Routine procedures include:

- Insulation Resistance Testing: To check the integrity of the motor and cable insulation against electrical shorts and leaks.

- Voltage and Current Measurement: To verify that voltages and currents are balanced across all phases, ensuring that the system is operating within specified limits.

- Thermal Imaging: To detect hot spots in electrical panels and components that may indicate overloads or faulty equipment.

Identifying and Troubleshooting Common Issues

Common issues in three-phase systems include phase imbalance, harmonic distortion, and overloads. Effective troubleshooting strategies involve:

- Monitoring Phase Load: Regularly checking and balancing loads to prevent phase imbalance, which can cause motor overheating and reduce efficiency.

- Harmonic Analysis: Using specialized meters to identify and mitigate harmonic distortions that can affect power quality and lead to equipment malfunction.

- Circuit Analysis: Inspecting and testing circuit components to identify and replace faulty elements like breakers, fuses, and connectors.

Commercial and Industrial Uses of Three-Phase Power

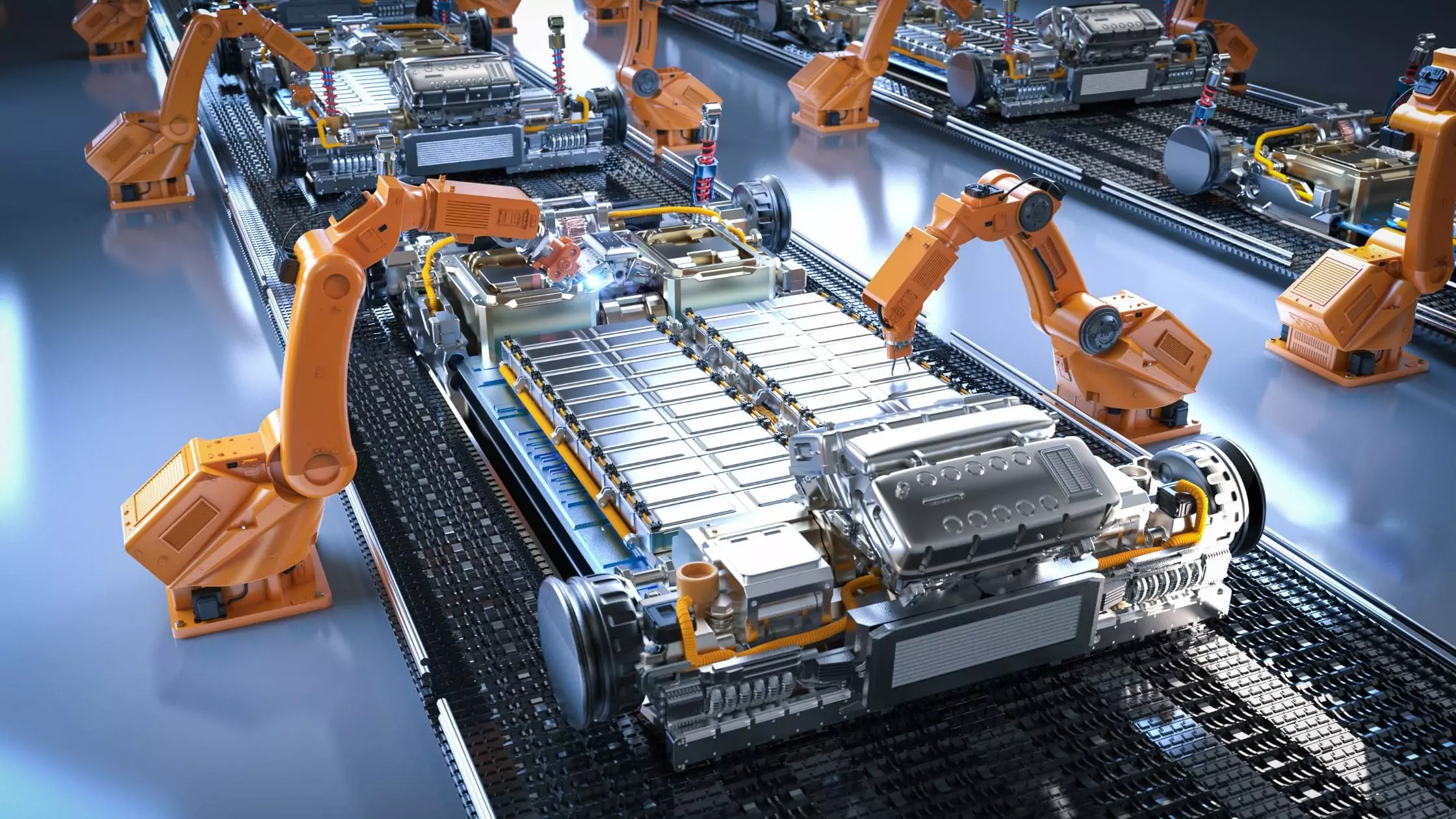

Three-phase power systems are a critical infrastructure component in various sectors due to their efficiency and ability to handle high loads. Here are specific examples demonstrating the versatility and essential nature of three-phase power in commercial and industrial settings:

- Manufacturing Plants: Three-phase power is pivotal for operating heavy machinery such as lathes, mills, and presses which require consistent and robust power supply to maintain productivity.

- Data Centers: To manage vast arrays of servers and cooling systems efficiently, data centers rely on three-phase power to ensure stable, uninterrupted power supply and to handle the high energy demands.

- HVAC Systems: Large commercial buildings use three-phase power for centralized HVAC systems, which benefits from the balanced load distribution to operate large motors and compressors effectively.

- Water Treatment Facilities: Three-phase systems drive high-power pumps and blowers crucial for water purification processes, ensuring reliable and efficient plant operations.

- Agricultural Operations: Farms utilizing modern equipment for irrigation and crop processing use three-phase power to operate high-capacity systems needed for planting, harvesting, and processing crops.

- Telecommunications Facilities: These facilities use three-phase power to ensure redundancy, reliability, and efficiency in operations critical for maintaining communication networks.

- Electric Vehicle Charging Stations: As EV adoption grows, three-phase power is used in fast-charging stations to quickly deliver power to electric vehicles, reducing charging times significantly.

- Mining Operations: Three-phase power is essential in mining for operating heavy drilling and extraction equipment deep underground, where reliable power is critical for safety and operational efficiency.

Conclusion

Understanding three-phase power is crucial for professionals and enthusiasts within the electrical and industrial sectors. This knowledge extends beyond the basics of electricity to encompass a comprehensive grasp of how power is generated, distributed, and utilized in more efficient and effective ways in various settings. The advantages of three-phase power, including its efficiency in power transmission and its capacity to handle heavier loads with less material cost, make it indispensable in modern industrial applications.

Recognizing the significance of three-phase power enables better planning, installation, and maintenance of electrical systems, ensuring they operate at peak efficiency while adhering to safety standards. For industries that rely heavily on robust machinery, such as manufacturing plants and data centers, three-phase power is not merely an option but a necessity for operational success.

FAQs

1. Is it Cheaper to Run 3-Phase?

Yes, it is generally cheaper to run three-phase power for several reasons:

- Efficiency in Energy Use: Three-phase power systems use less conductor material to transmit electrical power compared to single-phase systems, which can significantly reduce costs in systems requiring high power levels.

- Reduced Power Loss: Three-phase systems experience lower power loss during transmission, making them more efficient and cheaper to operate over long distances.

- Equipment Longevity: Equipment running on three-phase power often runs more smoothly and with less vibration, reducing maintenance costs and prolonging equipment life.

These factors contribute to the cost-effectiveness of using three-phase power in commercial and industrial settings, especially where high energy loads are a constant.

2. What is a Three-Phase Battery?

A three-phase battery does not refer to a specific type of battery but rather to a battery system that is used in conjunction with a three-phase power system. In such setups, the battery system may be designed to:

- Provide Backup Power: Ensuring uninterrupted power supply during outages.

- Enhance Power Quality: Helping to stabilize the grid and smooth out voltage fluctuations.

- Store Excess Power: Accumulating energy during low demand periods for use during peak demand.

These battery systems are particularly beneficial in industrial and renewable energy applications, where managing load and ensuring consistent power quality are critical. To properly charge a three-phase battery system to ensure consistency in the operations you will require an industrial battery charger.

相关推荐

- Forklift Charging: How to Charge a Forklift and Tips When Choosing a Forklift Battery Charging System

- How to Charge Automated Guided Vehicle: Charging AGV Guide

- Industrial Battery Charging: Methods, Best Practices and Safety Precautions

- Is There a Difference Between Industrial Batteries and Regular Consumer Batteries?

- What is an Industrial Battery: Definition, Types, Components & Applications

© 2025. All Rights Reserved. 琼ICP备88888888号