- 【Alltruth Limited】Welcome to Alltruth Power(www.alltruthpower.com), We provide you professional power solutions.

- Make a call:138 5726 9602

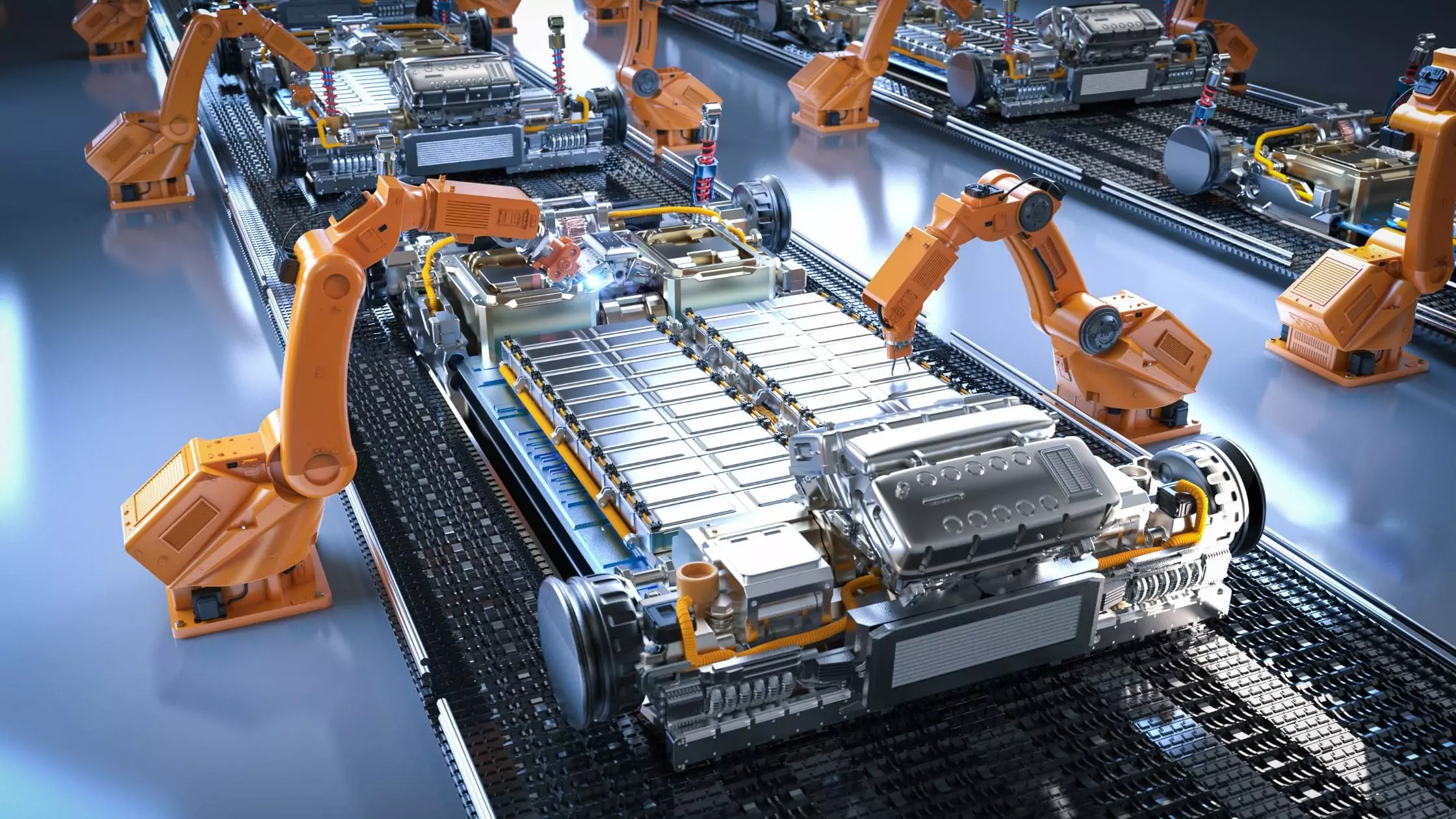

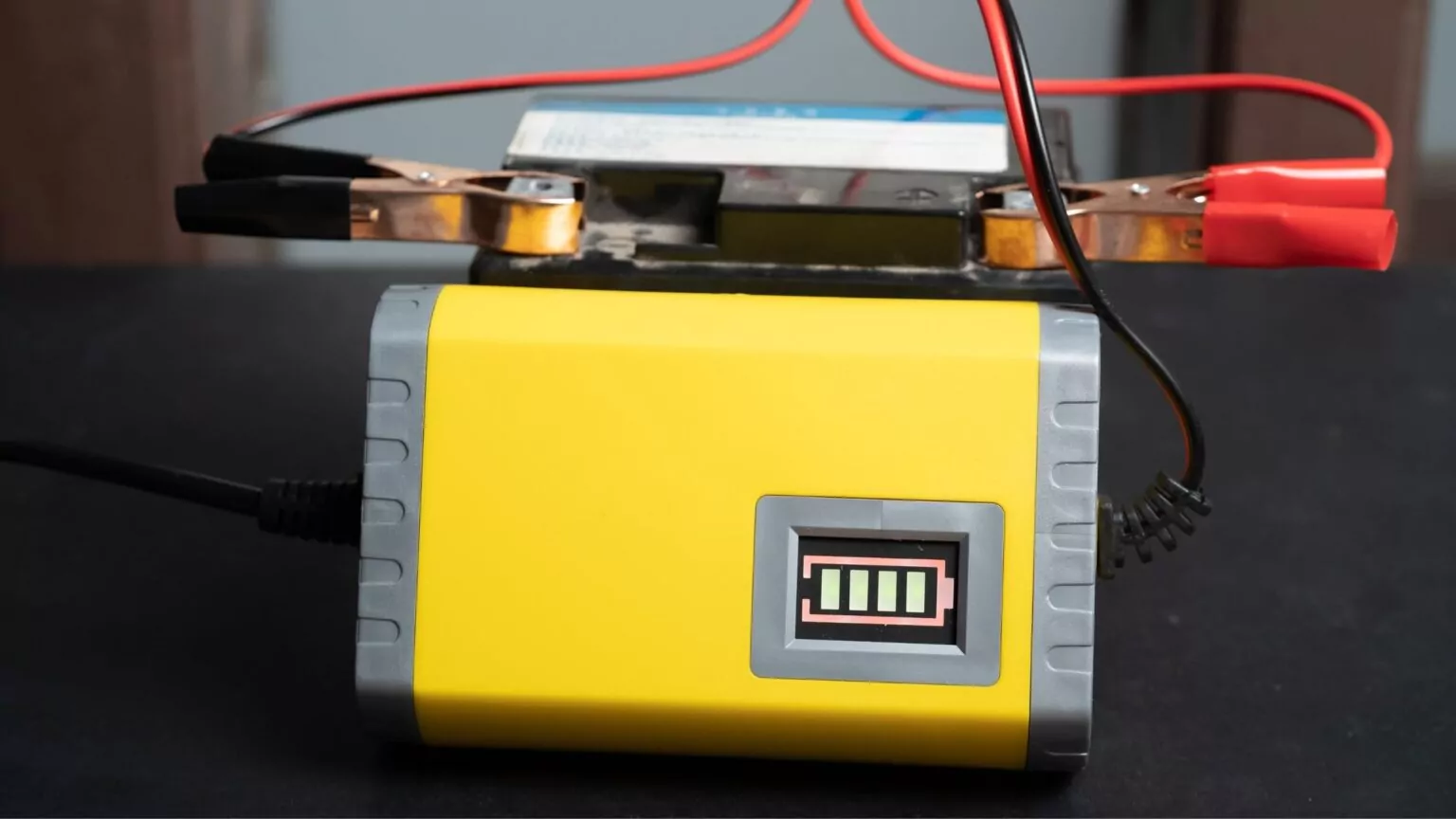

An industrial battery charger, unlike its consumer-grade counterparts, is а device engineered to meet the robust demands of heavy machinery and critical power systems.

In this guide, we will go deep into the essence, functionality, types, benefits and the applications of industrial battery chargers, showcasing their role in modern industrial operations.

What is an Industrial Battery Charger?

An industrial battery charger is a device that controls industrial battery charging of batteries in the operational efficiency of a wide range of industrial applications. Unlike a standard battery charger used in consumer electronics, these chargers are engineered to meet the rigorous demands of industrial equipment and power systems.

Their design and functionality cater to the unique needs of large capacity heavy-duty batteries, ensuring they deliver the necessary power for equipment such as forklifts, telecommunications systems, and emergency power sources.

How Does an Industrial Battery Charger Work?

An industrial battery charger employs three charging stages, bulk, absorption, and float, each designed to optimize battery health and longevity.

Understanding these stages is essential for anyone involved in the management of industrial equipment or the design of charging systems.

Here are descriptions of each stage:

- Bulk Stage: This is where the charger delivers a constant high current to the battery, rapidly bringing it up to around 70-80% of its full capacity.

- Absorption Stage: At this point, the charger lowers the current to a safer, steady rate to slowly bring the battery up to nearly 100% charge. This careful approach helps prevent damage that could result from too rapid charging.

- Float Stage: Once the battery reaches full charge, the charger reduces the current further to a minimal level. This maintains the battery at its peak capacity without overcharging, ensuring it remains ready for use without sustaining damage over time.

The essence of how industrial battery chargers operate lies in their ability to convert AC (alternating current) from the electrical grid into DC (direct current) that the battery can store. This process involves several key components:

- Rectifier: Converts AC to DC.

- Control Unit: Manages the flow of electricity to the battery, adjusting according to the battery’s charge state.

- Transformer: Modifies the voltage to match what the battery requires.

What are the Main Components of an Industrial Battery Charger?

Industrial battery chargers differ significantly from their consumer-grade counterparts, boasting components designed to meet the rigorous demands of industrial environments.

What Components are Essential to All Battery Chargers?

The architecture of a battery charger, whether for industrial use or consumer applications, includes several fundamental components that facilitate the charging process. Here is a list of these essential components and their functions:

- Rectifier: Converts alternating current (AC) from the power source into direct current (DC), the form of electricity that batteries can store.

- Transformer: Adjusts the voltage from the power source to the level required for the charging process.

- Control Unit: Acts as the brain of the charger, regulating the amount of current flowing to the battery to ensure efficient and safe charging.

- Circuit Protection: Protects the charger and battery from potential damage due to electrical surges, short circuits, or other anomalies.

What Components are Unique to Industrial Battery Chargers?

Industrial battery chargers possess additional, specialized components that distinguish them from typical consumer-grade chargers. These components are tailored to the needs of industrial applications, offering enhanced durability, reliability, and performance.

Examples from TL Power’s industrial battery chargers include:

- Integrated Die Casting Technique for Shell: This manufacturing process creates a robust and durable outer shell for the charger. The die casting technique allows for a high degree of precision in the charger’s physical structure, ensuring it can withstand the harsh conditions often found in industrial settings, such as extreme temperatures, moisture, and mechanical impact.

- Inside Filled with Organosilicon Encapsulant for Heat-Conducting, Anti-shock, Anti-aging: This component plays a crucial role in maintaining the charger’s longevity and performance. Organosilicon encapsulant is a compound used to fill the interior spaces of the charger, providing several benefits. It enhances heat conduction, ensuring that the charger dissipates heat efficiently during operation. This is vital for preventing overheating, which can reduce the charger’s lifespan and efficiency. Moreover, the encapsulant provides shock absorption, protecting the internal components from mechanical vibrations and impacts that are common in industrial environments. Lastly, its anti-aging properties help to protect against degradation over time, ensuring the charger remains reliable and effective for longer periods.

- Advanced Microprocessors: Industrial battery chargers often include advanced microprocessors that enable intelligent charging algorithms.

- Heavy-Duty Cooling Systems: To manage the heat generated during the charging process, especially in high-capacity charging applications, industrial battery chargers are equipped with heavy-duty cooling systems. These can include:

- Forced Air Cooling: Utilizing powerful fans to circulate air through the charger and keep the internal components at a safe operating temperature.

- Liquid Cooling Systems: Employed in very high-power chargers, these systems use a fluid to absorb and dissipate heat, allowing for more efficient cooling in tightly packed or high-temperature environments.

- Reinforced Connectors: Made with heavy-duty materials and designed to ensure a secure connection under all conditions.

- High-Capacity Cabling: To safely handle the high power levels without overheating or degrading over time.

What are Important Industrial Battery Charger Parameters?

The three main parameters of industrial battery chargers are voltage rating, current rating, and charging time. Below are eight critical parameters, each with specific metrics that are crucial to understand:

- Voltage Rating: Voltage rating is crucial to ensure compatibility with the battery being charged. Common voltage ratings include 12V, 24V, 36V, 48V, 60V, 72V and 80V. Matching the charger’s voltage rating with the battery’s voltage is essential for safe and efficient charging.

- Output Voltage Range: The output voltage range indicates the range within which the industrial battery charger can operate effectively. For example, a charger might have an output voltage range of 20V to 180V, accommodating different battery voltages and ensuring flexible use across various applications.

- Input Voltage Range: The input voltage range specifies the range of voltage that the charger can accept from the mains supply to operate effectively. For example, an industrial battery charger might have an input voltage range of 100V to 240V AC, allowing it to be used in different geographic regions with varying mains voltages and ensuring compatibility with a wide range of power sources.

- Current Rating (Amperage): The current rating, measured in amperes (A), specifies the amount of current the industrial battery charger can deliver. Output current ranges from 5A to 100A. Higher current ratings result in faster charging times. For instance, a 50A charger will charge a battery faster than a 20A charger, provided the battery can handle the higher current.

- Operating Temperature: Typical operating temperatures might range from -10°C to 50°C (14°F to 122°F). Ensuring the charger operates within this range helps maintain efficiency and longevity. There are industrial battery chargers with higher operating temperature ranging from -30°C to 65°C (-80℉ to 149℉).

- Input Phase: The input phase refers to the electrical phase configuration required by the charger. Most industrial chargers require either single-phase or three-phase power. For example, a charger might require a three-phase 208V input, which is common in industrial settings.

- Efficiency: Charger efficiency, often expressed as a percentage, indicates how well the charger converts electrical energy from the power source into stored energy in the battery. High-efficiency industrial battery chargers like the ones manufactured by TL Power, typically above 90%, reduce energy loss and lower operating costs.

- Noise: refers to the level of electrical interference or unwanted signals produced by the charger during operation. It is typically measured in terms of ripple voltage or as a decibel (dB) level. For example, an industrial battery charger might have a noise level of 50 mV ripple, indicating the amount of AC noise present in the DC output. Typical noise levels for most industrial battery chargers is below 55dB.

What are the Features of an Industrial Battery Charger?

All industrial chargers are equipped with advanced technologies and features designed to optimize All industrial chargers are equipped with advanced technologies and features designed to optimize charging processes, extend battery life, and ensure the safety of both the equipment and operators.

Advanced Charging Technologies

- Intelligent Charging Algorithms: These systems use data from the battery to adjust charging rates dynamically, optimizing each charging cycle to extend battery life and performance.

- Microprocessor-Controlled vs. Stand-Alone Chargers: Microprocessor-controlled chargers offer precise control over the charging process, monitoring battery conditions and adjusting parameters in real-time for maximum efficiency. Stand-alone chargers, while simpler, cannot adjust to varying battery conditions, making microprocessor-controlled options preferable for industrial applications.

Safety and Protection Features

Safety is paramount in industrial settings, and battery chargers incorporate several features to prevent accidents and equipment damage:

- Burnout Protection: Chargers automatically reduce the charging current if internal temperatures exceed safe levels and shut down if ambient temperatures reach excessive levels, resuming only when temperatures normalize.

- Protection for Reverse Connection of Batteries: Chargers are designed to disconnect internally if a battery is connected in reverse, preventing damage to both the battery and charger.

- No-Load Protection: Ensures the charger does not output when no battery is connected, avoiding energy waste and potential safety hazards.

- Short Circuit Protection: In the event of an output short circuit, the charger disconnects from the battery, requiring troubleshooting before charging can resume.

- Automatic Shutoff When Fully Charged: This feature prevents overcharging, extending the battery’s lifespan and maintaining its capacity.

Remote Monitoring and Management

Industrial battery chargers often include capabilities for remote monitoring and management, allowing operators to oversee the charging process from a distance. This feature is essential for:

- Ensuring chargers are operating correctly and efficiently.

- Identifying and addressing potential issues before they result in downtime.

- Optimizing the charging schedule and energy usage based on real-time data.

What are the Different Industrial Battery Charger Types?

Industrial battery chargers come in various types, each designed to meet specific operational needs and battery chemistries.

Understanding these types and their applications is essential for selecting the right charger to maximize productivity and extend battery life.

Single Phase

Single phase industrial battery chargers are suited for environments with lighter power demands. They are typically used in smaller operations or where the electrical infrastructure cannot support the more intensive requirements of three-phase power. Ideal for:

- Small to medium-sized warehouses

- Light manufacturing facilities

- Retail and office environments where less intensive use of battery-powered equipment is observed

These chargers are compatible with a wide range of battery types but are particularly effective for charging lead acid and AGM (Absorbent Glass Mat) batteries.

Three Phase Battery Chargers

Three phase industrial battery chargers provide a more efficient and faster charging solution, suitable for operations with high energy demands that can support three phrase power. These chargers are designed for:

- Large manufacturing plants

- Extensive warehousing operations

- Any setting where equipment operates across multiple shifts or around the clock

They are highly effective in environments that utilize a large forklift fleet or other heavy-duty battery-powered machinery, ensuring equipment is charged and ready for use with minimal downtime.

Float Chargers

Float chargers are designed to maintain a battery at its optimal charge level, supplying a trickle charge that compensates for the natural discharge over time. Ideal applications include:

- Emergency and backup power systems

- Telecommunications

- Utility services

Float chargers are critical for ensuring that batteries remain charged and ready for immediate use, particularly in applications where reliability is expected 24/7.

Forklift Battery Chargers

Specifically designed for the demanding requirements of forklift charging, these chargers are built to accommodate the robust use patterns of material handling equipment. They are ideal for:

- Warehousing and distribution centers

- Manufacturing facilities with material handling needs

- Any environment where forklifts are used extensively

Forklift battery chargers often come with features such as opportunity charging capabilities, allowing batteries to be partially charged during breaks to extend operational availability.

High-Frequency Chargers

High-frequency chargers use advanced technology to provide a more efficient charge, reducing energy consumption and improving battery life. These chargers are best suited for:

- Operations looking to reduce their energy footprint

- Facilities with high energy costs

- Environments where battery efficiency and longevity are priorities

Their efficient operation makes them a popular choice for a wide range of industrial applications, from warehousing to manufacturing.

Fast Chargers

Designed for rapid charging, fast chargers minimize downtime by quickly bringing batteries up to a usable charge level. They are particularly beneficial for:

- Operations with continuous or multi-shift use of equipment

- Settings where equipment cannot be easily swapped out for charging

- High-demand environments where time is a critical factor

Fast chargers can significantly enhance operational efficiency by reducing the time equipment is out of service for charging.

Opportunity Chargers

Opportunity chargers allow for charging batteries during short breaks, lunches, or shift changes, minimizing downtime and enhancing productivity.

Ideal for environments where equipment is used in multiple shifts, like warehouses, distribution centers and manufacturing facilities. These chargers provide the flexibility to keep batteries sufficiently charged throughout operational hours without requiring long charging periods.

Multi-Bay Chargers

Designed to charge multiple batteries simultaneously, multi-bay chargers are essential for operations that use a large number of battery-powered devices or vehicles, such as facilities with extensive fleets of forklifts, electric vehicles, or portable equipment requiring frequent battery swaps.

These chargers optimize space and improve efficiency by allowing several batteries to be charged in a single location.

Switch-Mode Battery Chargers

Switch-mode battery chargers use high-frequency electronics to offer more efficient and faster charging compared to traditional chargers. These chargers are lighter, more compact, and generate less heat, making them suitable for a variety of industrial environments.

Smart Chargers

Smart chargers incorporate advanced technology to monitor the battery’s condition and adjust the charging process accordingly. These chargers can extend battery life and improve performance by preventing overcharging and adapting to the battery’s needs.

Any industrial setting where battery health, longevity, and operational efficiency are priorities, including logistics and transportation companies will benefit from smart chargers.

What are the Benefits That Industrial Battery Chargers Bring to Industries?

The advantages that industrial battery chargers bring to various industries are both wide-ranging and impactful. Here are eight key benefits:

- Extend Battery Life: By employing advanced charging techniques that prevent overcharging and undercharging, industrial battery chargers help in significantly extending the lifespan of batteries.

- Increase Productivity: With features like opportunity charging and fast charging, these chargers minimize downtime for equipment, leading to higher productivity and efficiency in operations.

- Improve Energy Efficiency: Many industrial battery chargers are designed to optimize the charging process, reducing energy consumption and contributing to lower operational costs.

- Enhance Safety: Built-in safety mechanisms protect against overcharging, short circuits, and overheating, ensuring a safer work environment.

- Adapt to Various Battery Types: Industrial chargers can accommodate a wide range of battery chemistries, including lead acid and lithium ion, making them versatile for different equipment needs.

- Provide Remote Monitoring and Management: Advanced chargers come equipped with the capability for remote monitoring, allowing for better management of the charging process and timely intervention when needed.

- Increase Durability: Designed to withstand harsh industrial environments, these chargers are durable and reliable, ensuring long-term operation without frequent need for replacement.

- Meet Regulatory Compliance: Industrial battery chargers are often designed to meet stringent regulatory standards, ensuring that industries remain compliant with safety and environmental regulations.

What Are the Applications of an Industrial Battery Charger?

Industrial battery chargers are used across various industries to ensure efficient and reliable operation of equipment. These chargers are essential in sectors that rely heavily on battery-powered machinery. Here are ten different niches and industries that utilize industrial battery chargers:

- Material Handling and Warehousing: This includes forklift charging and automated guided vehicle (AGV) charging, both of which are crucial for maintaining efficient operations in warehouses and distribution centers.

- Construction Equipment: Various battery-powered tools and machinery in the construction industry require robust charging solutions to maintain productivity on job sites.

- Manufacturing Plants: Many manufacturing facilities use battery-powered equipment such as pallet jacks and lift trucks, necessitating reliable charging stations to avoid downtime.

- Telecommunications: Backup power systems for telecommunications equipment often rely on industrial batteries, which need consistent and dependable charging.

- Mining Operations: Battery-powered mining equipment, including transport vehicles and tools, requires industrial-grade chargers to withstand harsh conditions and maintain performance.

- Healthcare Facilities: Hospitals and clinics use battery-powered devices and equipment, such as mobile workstations and emergency backup systems, that depend on industrial chargers for reliable power.

- Public Transportation: Electric buses and other battery-operated public transport vehicles need efficient charging systems to ensure they remain in service and reduce operational delays.

- Renewable Energy Storage: Solar and wind energy systems often include battery storage solutions. Industrial battery chargers are essential for maintaining these energy reserves.

- Emergency Services: Battery-powered equipment used by emergency services, including portable lighting and communication devices, require dependable charging solutions to be ready for any situation.

- Agriculture: Battery-powered machinery and tools used in agriculture, such as electric tractors and irrigation systems, benefit from reliable industrial chargers to ensure seamless operation.

What are Important Compliances that Industrial Battery Chargers Should Cover?

Industrial battery chargers are subject to a wide array of compliances and standards, ensuring they meet the necessary safety, quality, and environmental benchmarks. Here’s an overview of the most critical compliances:

Safety Standards (UL, CSA, CE)

- UL (Underwriters Laboratories): Ensures chargers meet rigorous safety standards to prevent electrical and fire hazards.

- CSA (Canadian Standards Association): Similar to UL, but for the Canadian market, focusing on safety and performance.

- CE (Conformité Européenne): Mandatory for chargers sold in the European Economic Area, signifying conformity with health, safety, and environmental protection standards.

- CB (Certification Body) Scheme allows international recognition of products tested to applicable IEC standards, facilitating global market access.

- FCC (Federal Communications Commission) regulates interstate and international communications by radio, television, wire, satellite, and cable in the U.S., ensuring that electronic devices like battery chargers do not cause harmful interference.

EMC Directive

Ensures chargers do not emit or are not affected by electromagnetic interference, critical for chargers used in environments with sensitive electronics.

Energy Efficiency Regulations (Energy Star, ErP Directive)

- Energy Star: Recognizes chargers that meet specific energy efficiency criteria, helping businesses save costs and reduce environmental impact.

- ErP Directive: European regulation aimed at improving the environmental performance of products, including battery chargers, by setting design requirements.

RoHS Directive

Restricts the use of specific hazardous materials found in electrical and electronic products, ensuring that battery chargers are safer for the environment and human health.

REACH Regulation

Ensures chargers are manufactured using substances that do not harm human health or the environment, requiring companies to manage the risks associated with chemical substances.

Battery Charging Standards (IEEE)

Defines the operational specifications for battery chargers, ensuring compatibility and efficiency in charging processes.

Environmental Regulations

Includes various international, national, and local regulations aimed at protecting the environment from the impacts of manufacturing, using, and disposing of battery chargers.

Documentation and Labeling Requirements

Chargers must be accompanied by proper documentation and labels that provide critical information on safe use, disposal, and compliance with standards.

Quality Management Systems (ISO 9001)

Ensures that manufacturers of industrial battery chargers follow a systematic approach to managing their processes and systems to meet customer and regulatory requirements.

Product Specific Standards

Covers additional standards specific to the type, use, or design of the charger, ensuring they are suitable for their intended industrial applications.

KC and RCM

- KC (Korea Certification) is required for products sold in South Korea, ensuring they meet safety and performance standards.

- RCM (Regulatory Compliance Mark) signifies compliance with Australian and New Zealand technical standards, particularly regarding safety and electromagnetic compatibility.

CEC and DOE

- CEC (California Energy Commission) focuses on energy efficiency standards for electrical devices in California.

- DOE (Department of Energy) sets standards for energy efficiency across various products in the United States.

CP65 and ECE R10 Directives

- CP65 (California Proposition 65) requires businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects, or other reproductive harm.

- ECE R10 Directive involves regulations by the Economic Commission for Europe (ECE) concerning the electromagnetic compatibility of vehicles and automotive components.

Maintenance and Troubleshooting of Industrial Battery Chargers

Proper maintenance and efficient troubleshooting are essential to maximizing the performance and lifespan of industrial battery chargers. Here are several key considerations:

- Routine Inspections: Regularly check the charger for any signs of wear or damage, particularly to cables and connectors, to prevent accidents and ensure optimal operation.

- Cleanliness: Keeping the charger clean from dust and debris can prevent overheating and ensure efficient operation.

- Firmware Updates: For smart chargers, ensure that the firmware is regularly updated to benefit from improved charging algorithms and new features.

- Calibration: Periodically calibrate the chargers according to the manufacturer’s guidelines to maintain accuracy in charging.

- Troubleshooting Common Issues: Common issues like failing to charge, charging slowly, or overheating require systematic troubleshooting. This often involves checking power sources, connections, and settings, or consulting the manufacturer’s support resources for guidance.

How to Select the Right Industrial Battery Charger?

Selecting the ideal industrial battery charger for your operations involves considering several factors to ensure compatibility, efficiency, and cost-effectiveness.

Whether the need is for rapid charging, flexibility, or maximizing battery lifespan, there is an industrial battery charger designed to meet those specific requirements, providing a critical component in the management and maintenance of industrial battery-powered equipment.

Here’s are eight factors to keep in mind:

- Battery Type: Different chargers are optimized for different battery chemistries, such as lead acid or lithium ion.

- Charging Specifications: Match the charger’s output with the battery’s voltage and current requirements.

- Equipment Utilization: Consider how the equipment is used and the feasibility of opportunity charging or the need for rapid charging solutions.

- Electrical Infrastructure: Ensure your facility’s power supply is compatible with the charger’s requirements.

- Physical Space Requirements: Assess the available space for charging stations, considering the possibility of multi-bay or wall-mounted chargers if space is limited.

- Efficiency: Efficient chargers reduce energy consumption and operating costs while providing faster charging times.

- Reliability: Choose chargers known for durability and consistent performance, minimizing downtime due to charger malfunctions.

- Total Cost of Ownership: Consider not only the purchase price but also long-term costs related to energy consumption, maintenance, and the potential extension of battery life.

Sustainability and Environmental Considerations

Environmental considerations are neverending, stretching from manufacturing processes through to end-of-life disposal. Manufacturers are actively seeking solutions to mitigate environmental impacts, focusing on several key areas:

- Eco-Friendly Materials: Employing recyclable and less toxic materials in construction to minimize environmental harm.

- Energy Efficiency: Designing chargers that consume less power, contributing to lower carbon footprints.

- Longevity and Durability: Extending the lifespan of chargers to reduce waste and the demand for raw materials.

- Battery Efficiency: Improving charging efficiency to extend battery life, thereby reducing the frequency of battery replacement and associated waste.

- Recycling Programs: Facilitating the recycling of old chargers and batteries to ensure proper handling of hazardous materials.

- Reduced Emissions: Adopting manufacturing processes that emit fewer pollutants, aligning with global efforts to combat climate change.

- Compliance with Environmental Regulations: Meeting or exceeding standards set by environmental protection agencies around the world.

- Innovative Technologies: Exploring new charging technologies that promise lower environmental impacts.

These initiatives highlight the industry’s commitment to sustainability, ensuring that industrial battery chargers contribute positively to environmental stewardship.

What are leading industrial battery chargers manufacturers?

The landscape of industrial battery charger manufacturing is diverse, featuring companies that specialize in a broad range of products tailored to meet the demanding needs of various industries. These manufacturers are recognized for their innovation, reliability, and commitment to quality, providing solutions that enhance operational efficiency and sustainability. Here’s a closer look at some of the leading names in the industry:

IBCI

Industrial Battery & Charger, Inc. (IBCI), with a presence across the Southeast including states like Alabama and Virginia, stands as a forefront provider of motive and stationary power solutions. Boasting a network of over 16 sales and customer service centers, IBCI’s team of 200 associates, inclusive of 60 certified technicians, underscores their dedication to delivering top-tier products and unmatched support. Their comprehensive service vehicles further ensure responsive and effective customer service.

TL Power

Established in 2014, TL Power has quickly ascended as a premier manufacturer of industrial battery chargers, operating out of a sprawling 45,000 square meter facility in Weihai, Shandong, China. Specializing in IP65 sealed chargers with outputs ranging from 300W to 9000W, TL Power caters to a vast array of applications. Their commitment to excellence is evident in their IATF16949 certification and a suite of product certifications including UL, CE, and more. TL Power’s chargers are rigorously tested to ensure they meet the highest standards of safety, reliability, and durability.

ABC Chargers

American Battery Charger (ABC Chargers) brings over 40 years of engineering expertise to the battery and charger industry since its inception in 1988 in Smithfield, Rhode Island. Serving the Industrial and Railroad Transit sectors, ABC offers an array of chargers for standby power applications, boasting certifications like UL and CE for selected models. Their product line ranges from compact 12V-6A chargers to robust 240V-600A solutions, emphasizing reliability across their offerings.

Micropower

Micropower emerges as a global authority in providing cutting-edge solutions for battery chargers, power supplies, and modular Li-ion battery systems. With an emphasis on energy-efficient, advanced technology solutions, Micropower invests in continuous development at their R&D centers in Sweden and Finland. Their industrial battery chargers are known for their dependable hardware, smart software functionalities, and customer-centric designs, serving as a testament to their innovative approach to energy storage.

Prestolite Power

With roots dating back to 1917, AMETEK Prestolite Power (formerly Hobart Brothers Battery Charger Division) has been a pillar in setting the standard for the material handling industry’s forklift battery charging needs. Operating from Troy, Ohio, USA, Prestolite Power’s portfolio spans High Frequency, Ferroresonant, and SCR chargers, demonstrating their versatility and commitment to industrial excellence. Their wide-ranging products underscore their legacy in providing high-quality industrial battery charging solutions.

Conclusion

Industrial battery chargers are indispensable in modern industries, powering essential machinery and vehicles. Choosing the right charger involves understanding specific operational needs, the impact of technological advancements, and environmental considerations.

The evolution of charging technologies continues to enhance the efficiency, reliability, and sustainability of these vital devices.

As industries look towards the future, the role of industrial battery chargers in enabling growth and supporting sustainable practices becomes increasingly significant.

FAQs

1. Are industrial battery chargers loud?

Industrial battery chargers, particularly those designed with modern specifications like TLpower chargers, operate at sound levels of ≤55dB. This noise level is comparable to a quiet conversation, ensuring they do not contribute significantly to workplace noise pollution.

2. What is the operating temperature of an industrial battery charger?

The operating temperature range for industrial battery chargers typically spans from -30°C to 65°C (-80℉ to 149℉). This wide range ensures that chargers can function effectively in various environmental conditions, from cold storage areas to hot industrial environments.

3. What is the efficiency level of industrial battery chargers?

Modern industrial battery chargers achieve efficiency levels of ≥90%. This high efficiency signifies that a minimal amount of electrical energy is lost during the conversion process, making these chargers both cost-effective and environmentally friendly.

相关推荐

- Forklift Charging: How to Charge a Forklift and Tips When Choosing a Forklift Battery Charging System

- How to Charge Automated Guided Vehicle: Charging AGV Guide

- What is Three Phase Power: Definition, Working Method and Applications

- Industrial Battery Charging: Methods, Best Practices and Safety Precautions

- Is There a Difference Between Industrial Batteries and Regular Consumer Batteries?

© 2025. All Rights Reserved. 琼ICP备88888888号